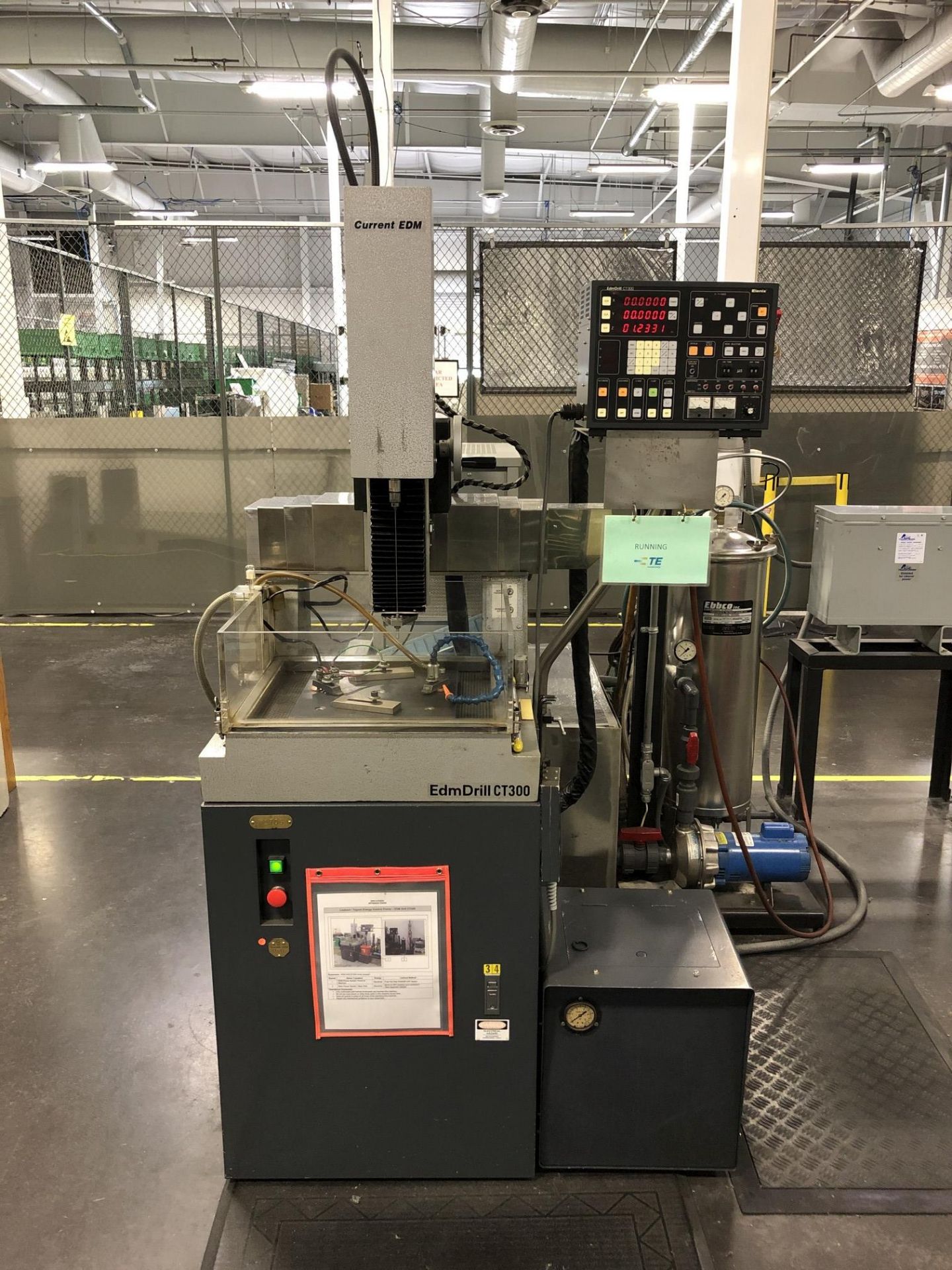

BELMONT "SY-SERIES" ZNC

MANUAL HIGH SPEED EDM DRILLING MACHINE

FOR CARBIDE APPLICATIONS USING OIL DIELECTRIC

MODEL: SY-M-2535S S/N: GY13M2535S179 NEW: 2013

The SY-M-2535S control and quick response Z Axis

DC Servo motor, along with the standard triplex,

three plunger high pressure dielectric pump, combine

features that create a system to remove the dis-

integrated material rapidly, promoting smaller,

faster, and deeper drilling possibilities.

The Auto-Z feature compensates for electrode wear and

resets the Z Axis position at first spark. Setting

the depth of cut, retract stroke, and programming all

machine settings are accomplished directly on the

control.

MACHINE DESCRIPTION

The Belmont SY-M-2535S is a conventional "C" frame

design. All sides are supported on linear roller

ways and use high precision ball screws assuring ease

of movement and absolute precision.

The X and Y Axes are equipped with linear bearing

ways and precision linear glass scales with five

micron resolution. This provides true, closed loop,

position feedback for precise part positioning

accuracy. Position readouts are displayed on the

control panel giving the operator a constant update

on the machine as it operates. The X Axis travel

is 13.7" and the Y Axis Travel is 9.8". All

information can be displayed in metric or inch units.

The EDM head, the Z Axis, has a DC Servo drive with

a travel of 16.1" thus allowing the use of 16.0"

electrodes, 13.3" usable length, for greater economy.

The head is mounted on the back slide with 7.8" of

travel. The guide height is adjustable, up to 6.1".

The minimum open height is 0.4" and the maximum is

8.2". Adjusting the guide height to increase the open

height will reduce the usable electrode length.

The precision ground stainless steel worktable is 23.6"

by 11.8" and is divided into four mounting surfaces

with a series of M-8 threaded holes. The table also

has two movable rails, which are drilled and tapped

to accept tooling for quick clamping and locating of

the work piece. The table is contained in a work tank

measuring 27.9" wide, 20.4" deep and 5.9" tall and will

accept work pieces up to 880 pounds.

The dielectric unit is a self priming triplex, three-

plunger pump, capable of producing 1,200 to 1,400

PSI. Average running pressure is 500 to 700 PSI.

This amount of pressure is required to create a dielectric

flow through the rotating tube electrode, offering it

stability at the point of eDM, creating optimum flushing

conditions.

The SY-M-2535S is specifically designed for carbide

applications and EDM oil is used as the dielectric.

Included with the machine is a closed loop filter system

that consists of a reservoir, single cartridge filter

unit with a 5 micron paper cartridge, and a pump used

tofill and circulate the oil in the work tank. The

reservoir has a 55 gallon capacity. The filter system

also includes a liquid chiller that will maintain a

consistent temperature of the oil dielectric.

POWER SUPPLY AND MACHINE CONTROL

Located in the base of the machine, the power supply

is built with thelatest state of the art electronics

providing high frequency cutting energy to the electrode,

with on and off times that are available in 10 settings

and up to 30 average amperes of power.

SPECIFICATIONS:

MAX. AMPS: 30 AMPS

TABLE SIZE: 23.6" x 11.8"

MAX. WORKPIECE WEIGHT: 880 LBS.

LONGITUDINAL TRAVEL: 13.7"

CROSS TRAVEL: 9.8"

Z AXIS SERVO TRAVEL: 15.7"

BACKSLIDE TRAVEL: 7.8"

OPEN HEIGHT, MIN. - MAX.: 0.4" - 8.2"

ELECTRODE DIAMETERS AVAILABLE: 0.01" - 0.11"

MAX. HEIGHT OF WORKPIECE: 8.6"

FLOOR SPACE (L x W x H): 80" x 80" x 88"H

WEIGHT: 1,860 LBS.

EQUIPPED WITH:

"HABOR PRECISE INDUSTRIES CO." MODEL HE-250SA

OIL COOLER UNIT

55 GALLONS OIL DIELECTRIC EXTERNAL TANK

EXTRA FILTERS

MANUAL FOR THE MACHINE

WIRED FOR 3/60/220 VOLTS, 3.5 KVA SERVICE

** INSPECT IN OUR HARRISON, NJ WAREHOUSE **

** "EXCEPTIONAL" CONDITION & APPEARANCE **