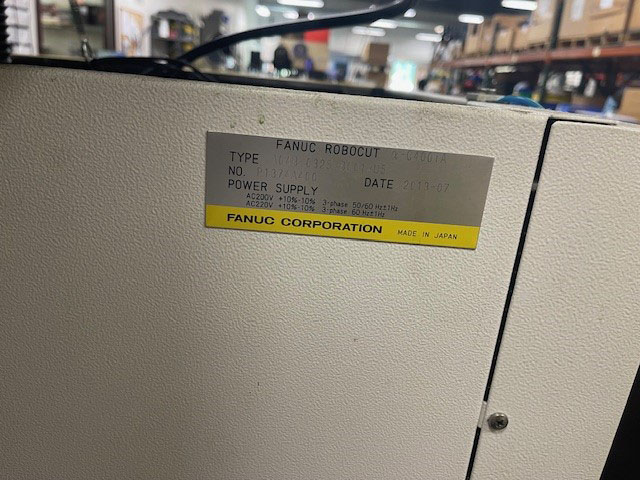

Fanuc Robocut Alpha C400iA CNC Wire EDM

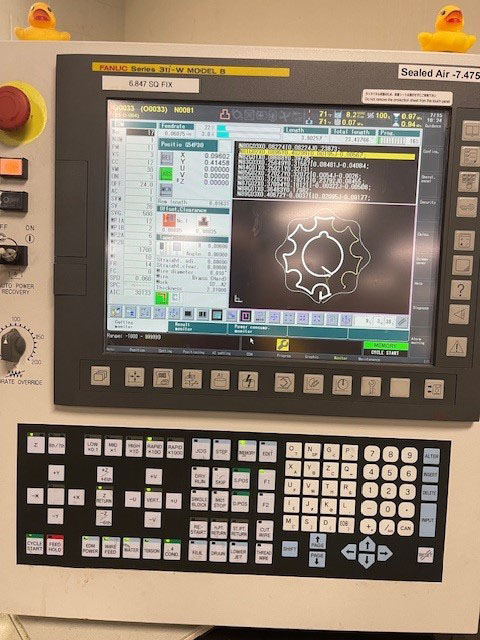

with Fanuc 31i-WB CNC Control

*** Made in Japan ***

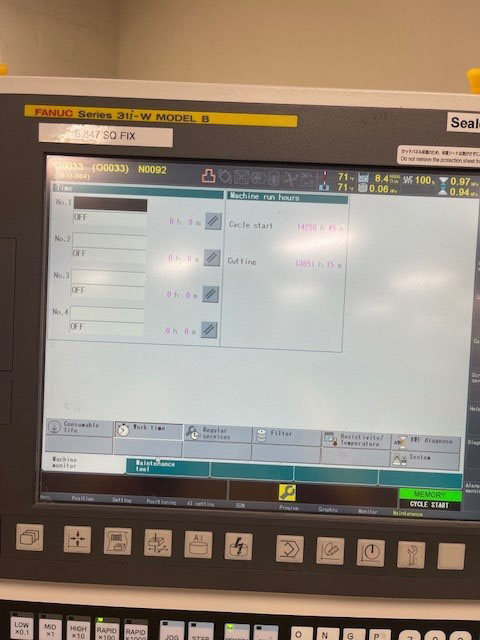

S/N: P1374A400 New: 2013

Special Note, Low Hours Machine:

Machine Tool Features:

• Travel

X Axis............................... 14.6”

Y Axis............................... 10.6”

Z Axis .............................. 10.2”

UV axes travel ...................... ± 2.362”

Rapid traverse ...................... 1 ~ 50/ min.

Work piece thickness @ taper Angle .. ± 12 @ 10 in

Manual threading (jet nozzle removed) ± 30 @ 3.26 in

* Requires optional Diamond guides ± 45 @ 1.6 in

• Positioning accuracy (X, Y) .......... ± 0.0001

• Repeatability (X, Y )................. ±0.000050

• Axes drive motors..................... AC Servo Motors

Direct coupled to ball screw

• Maximum cutting speed***

0.012” brass wire guides 2.4 in.

thick tool steel .................. 31 square in./hour

0.012” Coated wire 2.4”

thick D2 tool steel ............... 33.5 square in./hour

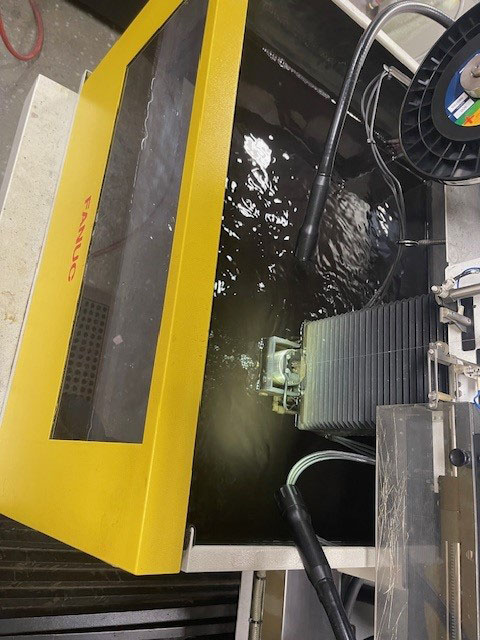

• Internal Worktank Size (X x Y x Z) ... 30.5” x 23.6” x 9.8”

• Maximum submerged cutting depth ...... 9.84”

• Maximum work piece weight ............ 1,100 lbs

• Wire feed system

Wire feed rate ..................... 0 ~ 590 IPM

Wire tension ....................... 200 ~ 2,500 g

Maximum wire spool weight .......... 35 lbs

Wire diameter (min. to max.) ....... 0.004 to 0.012”

• Wire guide – upper & lower guide ..... Round diamond die guide

• Dielectric fluid system

Tank cap. .......................... 145 gal

Chiller ............................ Standard

Dielectric fluid ................... Deionized water

Resin bottle (one plus a spare) .... 1 cu. ft

Filters (2 each).................... Cartridge

Filtering precision ................ 3 Micron

Dielectric fluid,

resistively control ............... NC Controlled

• Cutting conditions

Auto selection of 9 choices for 1 Cut ... Standard

Automatic selection of 9 choices

for multiple cut .................... Standard

Automatic selection of 3 choices

for micro finish cut ............... Standard

• Programming methods

G-Code Programming.................... Standard

Built-in easy conversational ......... Standard

Off-line system via RS232 or

Ethernet interface ................. Standard

Power Supply Features:

* Power Supply

Pulse generator type ................ Transistor driven

AC or DC.............................. Switchable

Power supply circuit ................. Transistor pulse circuit

No loading voltage ................... Setting range 0 – 13

Cutting voltage....................... Setting range 3 – 18

On time .............................. Setting range 1 – 255

Off time ............................. Setting range 2 – 300

Servo voltage ........................ Setting range 0 – 255

Programmable flushing ................ Setting range 1 - 18

Pulse mode............. Setting range – 1, 2, 3, 4, 11, 12, 13,

14 21, 31, 33, 41, 43

• Total power required ................. 13 KVA

(200/220 V ± 10%, 3 Phase, 60 Hz)

• Floorpace............................. 92” x 105”

• Machine weight........................ 4,000 lbs.

• Controlled axes ...................... X, Y, U, V, Z Plus optional rotary axis

• Least input increment ................ 0.000004”

• Least command increment .............. 0.00000004”

• Interpolation ........................ Linear, Circular

Additional Features of the FANUC C400iA Series

• Fanuc series 31i-WB CNC control with (1) 64bit and

(3) 32 bit processors

• 15” Color LCD with advanced Touch Screen technology

• Swivel Control Panel for easier operation

• Heidenhain linear glass scales – X and Y Axis only

• Fanuc serial/digital AC servo motors

• NC Command Resolution of 0.00000004”

• Seven (7) controlable axes (X, Y, U, V, Z, A & B)

• 30 degree + taper cutting capability (optional guides required)

• Absolute position encoder system for X, Y, U, V & Z axes

(no need to home the machine after start-up)

• Wire Tension Controlled via Twin Servo Motors (no powder brakes)

• Independent column mounted U and V axis slides

• Anti-Crash protection (X, Y, U, V, Z)

• Fanuc high speed fully digital / AC power supply

• Full Function Hand Held Pendant

• Simple and Quick On-Board Conversational Programming

• Servo Controlled automatic water level control in work tank

• Operator guidance screens for operation, alarms,

maintenance and parts

• (1) RS232C • (1) Ethernet port • (2) USB Ports

• (1) PCMCIA slot • Part program storage capacity

4 Megabyte (in control memory)

• Automatic power recovery

• Automatic restart

• Wire center path calculation G41/42

• Programmable Flushing

• AWF2 Function:

Fanuc is world renowned for having the

best AWF system on the market. The simplicity and

reliability make unattended operation a true reality.

Further upgraded for the iE series, the AWF2 offers the

following enhancements: ü Submerged initial threading up

to 200mm thick work pieces ü Improved Ai Automatic Wire

Repair in the cutting gap up to 150mm thick work pieces

AWF monitor screen allows easy set-up of the following

advanced functions: ü AWF skip function ü Retry skip

function ü AWF result screen ü RE-machining function

ü Pecking retry function ü Full-Retry function ü Retry

locations display ü Wire breakage locations display.

** Superior Condition & Appearance **

F.O.B. Our Harrison, NJ warehouse

Properly De-Installed by Fanuc EDM Including with Shipping Brackets