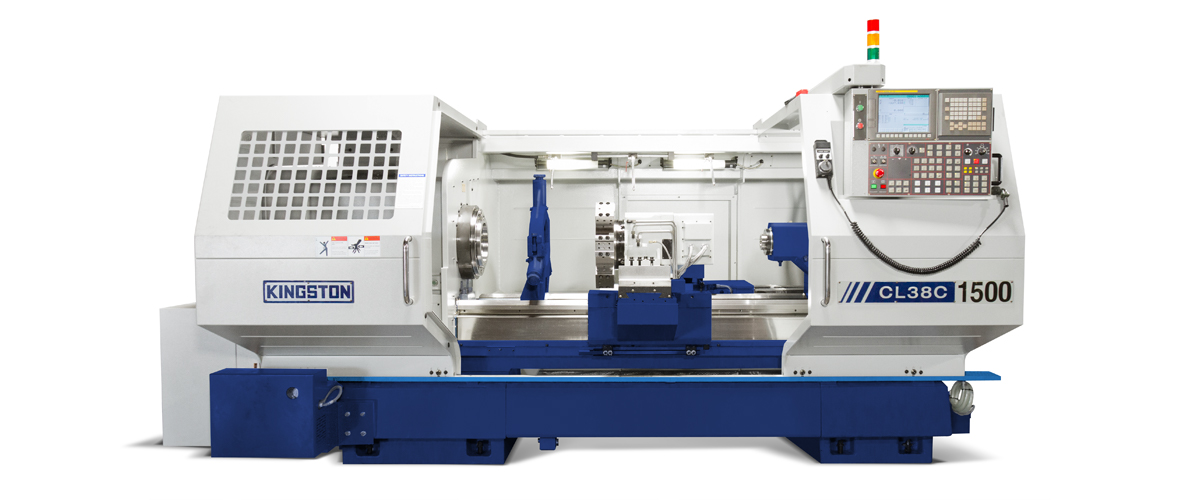

NEW KINGSTON CNC FLAT BED LATHE

MODEL: CL38

SPECIFICATIONS:

CAPACITY

SWING OVER BED ................... 26"

MAX. CUTTING DIAMETER ............ 14.5"

DISTANCE BETWEEN CENTERS ......... 40"/60"/80"/120"/160"

WIDTH OF BED ..................... 18"

HEADSTOCK

SPINDLE BORE ..................... 7.3"

SPINDLE MOTOR .................... 25 HP / 30 HP (30 min)

TYPE OF SPINDLE NOSE ............. A2-15

GEAR BOX

NUMBER OF SPEED RANGES ........... 2

SPINDLE SPEED (RPM) .............. 3 – 1000

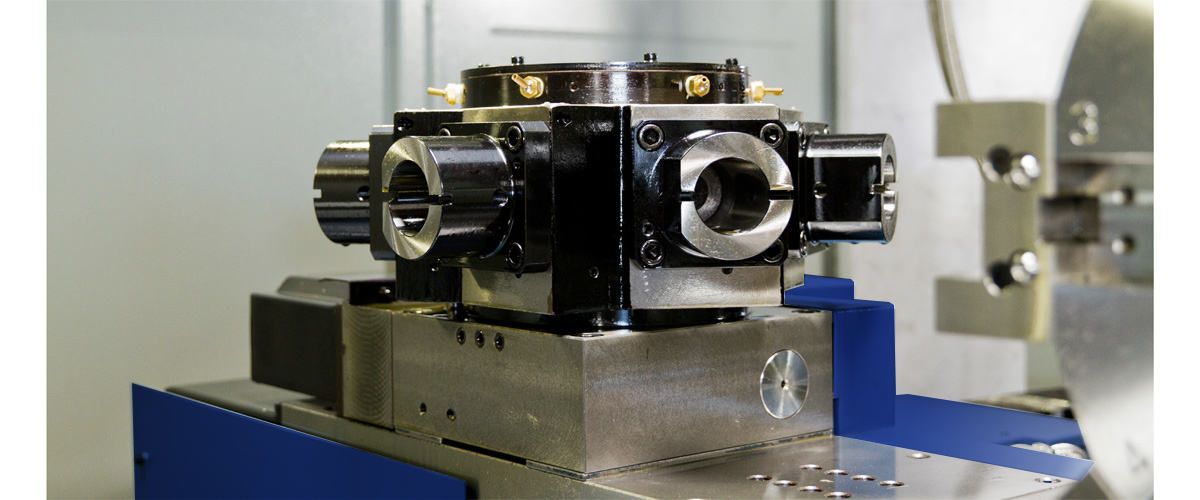

TURRET ........................... V8 HYDRAULIC & H6 SERVO (STD)

TRAVERSE

MAX. STROKE X-AXIS ............... 21.2"

MAX. STROKE Z-AXIS ............... 37.4"/57.1"/76.8"/126.8"/164.2"

RAPID TRAVERSE X-AXIS ............ 394"/min

RAPID TRAVERSE Z-AXIS ............ 394"/min

MOTOR

SERVO MOTOR X-AXIS ............... 3.6 HP

SERVO MOTOR Z-AXIS ............... 5.4 HP

BALL SCREW

X-AXIS ........................... Ø1.41”, P6

Z-AXIS ........................... Ø1.97",P8(80")/P12(120")/P16(160")

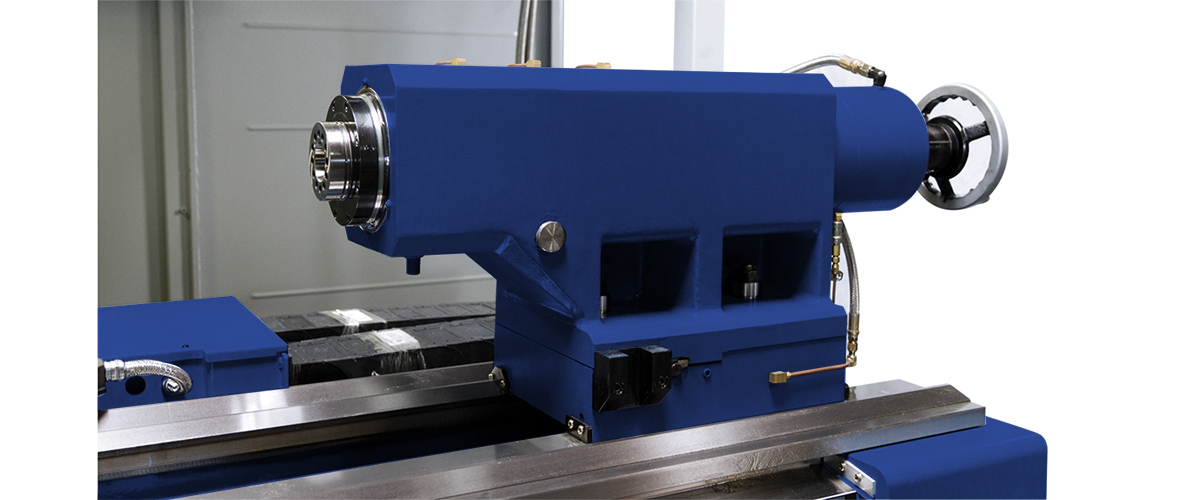

TAILSTOCK

TAILSTOCK QUILL CENTER ........... M.T. #5

TAILSTOCK QUILL DIAMETER ......... Ø5.9”

TAILSTOCK QUILL TRAVEL ........... 8.6”

EQUIPPED WITH:

BORE: 4.7" OR 7.3"

SWING: 26"

C.C.: 40" — 160"

25 HP / 30 HP (30 MIN)

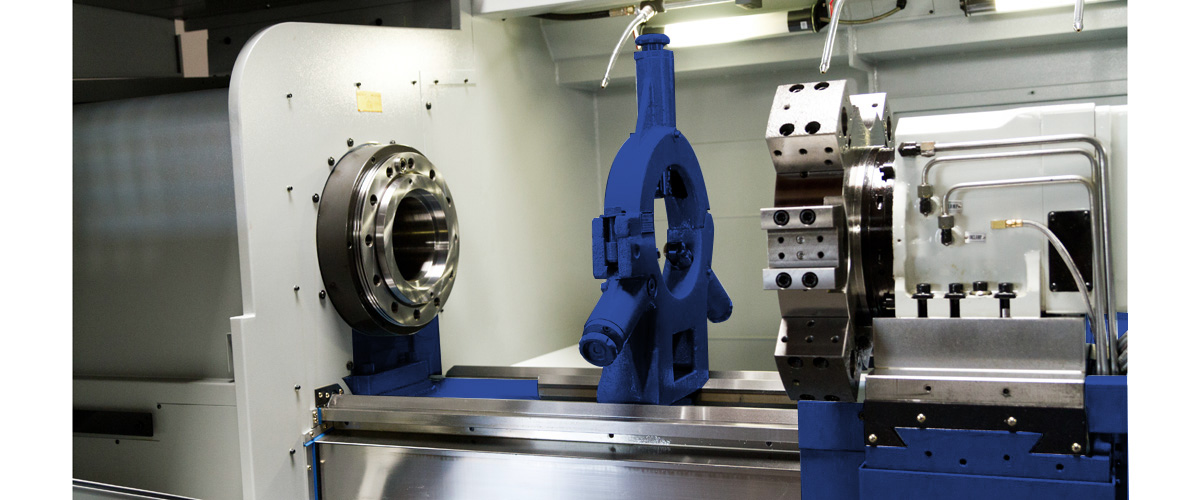

REAR CHUCK ADAPTER FOR CL38C (7.3" BORE)

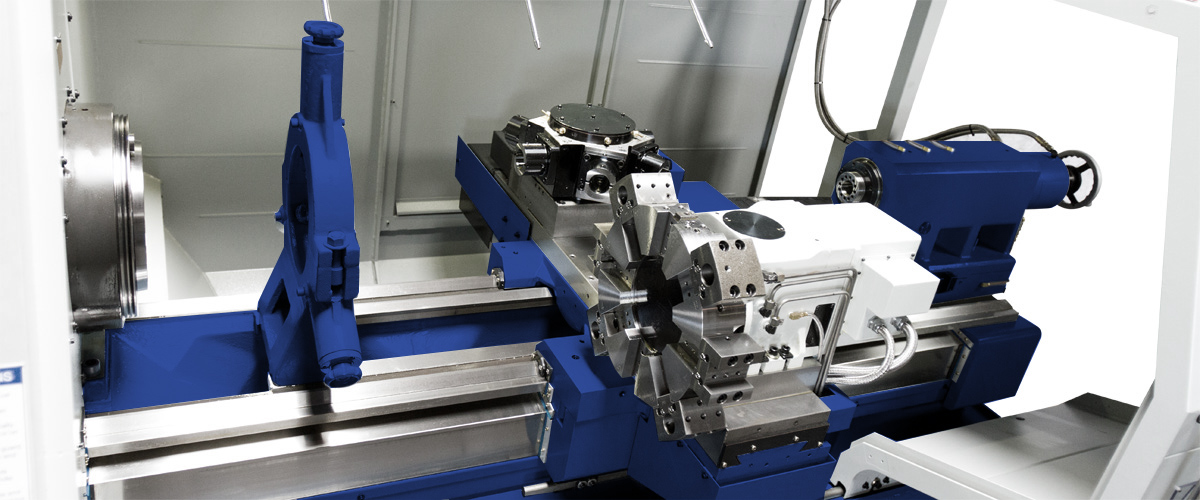

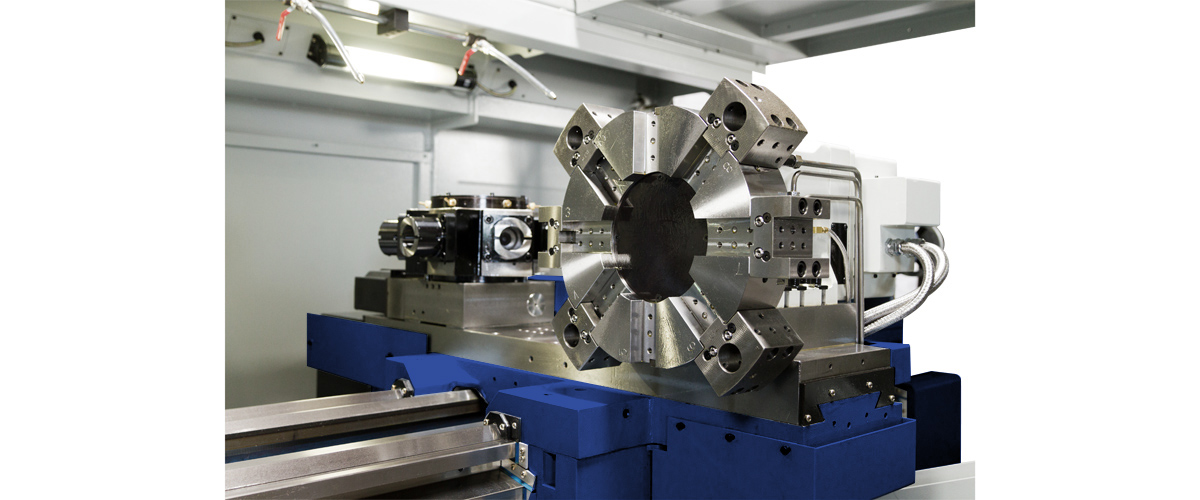

V8 FRONT & H6 REAR TURRETS

9.25" STEADY REST WITH ROLLER JAWS

ROTARY TAILSTOCK WITH CHUCK MOUNTING CAPABILITY

HYDRAULIC & MANUAL QUILL MOVEMENT

COOLANT SYSTEM W/ 6-BAR PRESSURE

WATER SPRAY GUN FOR CHIP CLEANUP

REAR CHIP CONVEYOR

FANUC 0ITF CONTROLLER WITH MANUAL GUIDE I, 10.4” LCD MONITOR

OPTIONAL ACCESSORIES

SAUTER V12 LIVE TOOLING TURRET + 2.5° C-AXIS SPINDLE INDEXING

15.9" STEADY REST

ADDITIONAL 9.25" STEADY REST

4.75" FOLLOW REST

A2-11 REAR CHUCK ADAPTER FOR CL38A (4.7" BORE)

BORING BAR SUPPORT ON CROSS SLIDE

EXTRA HIGH PRESSURE COOLANT PUMP

FANUC ARBITRARY SPEED THREADING

FULL ENLCOSURE

MANUAL, HYDRAULIC, & AIR CHUCKS

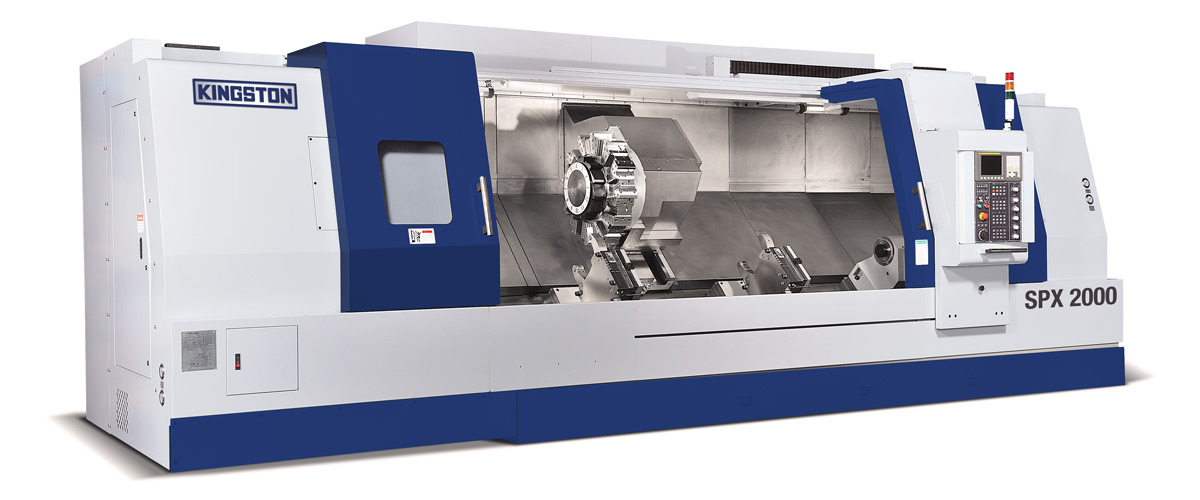

Kingston’s versatile CL38 model is designed for universal workpieces in a variety of industries, including energy, mining, textile, paper, and transportation. The CL38 features 26” swing, a choice of 4.7” or 7.3” bore, and lengths from 40” – 160". It is equipped with a powerful 30 HP spindle motor, a sub-spindle tailstock ready to mount a chuck, and both V8 and H6 servo turrets – with a maximum cutting diameter of 14.5” between turrets. This flexibility and ease of use make the CL38 one of our most popular CNC models.