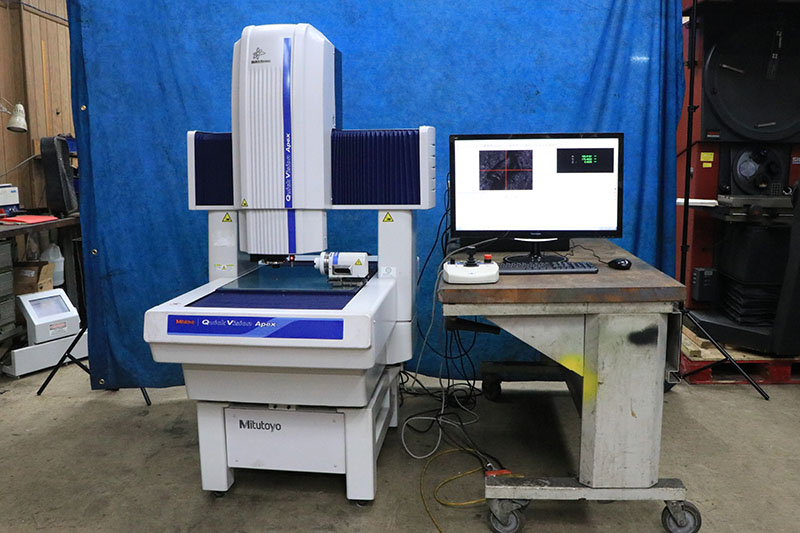

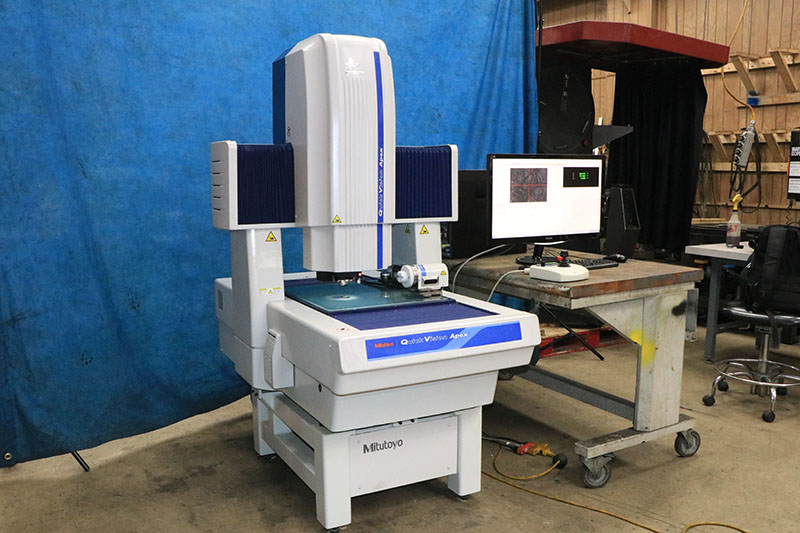

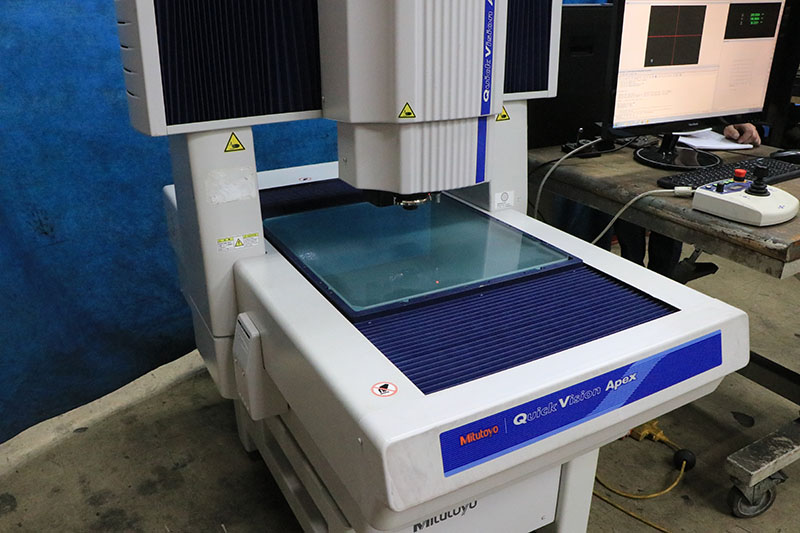

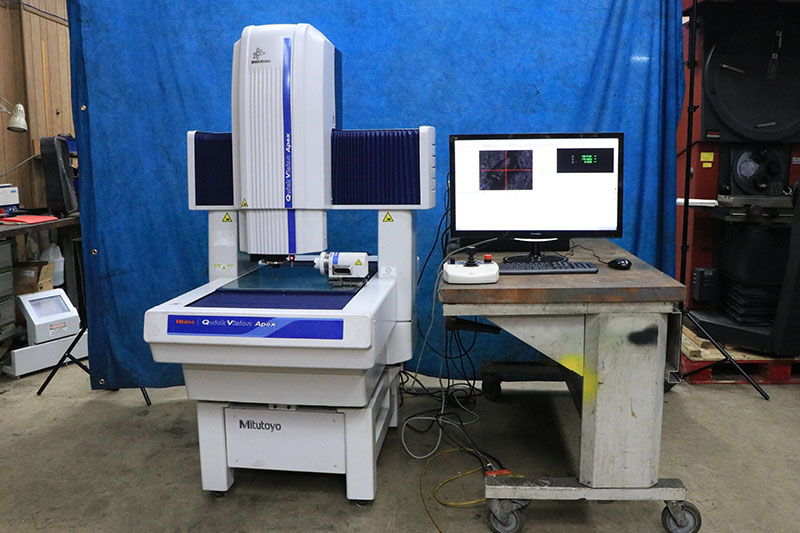

Mitutoyo Quick Vision Apex

CNC Vision Measuring System,

3D Non-Contact CMM,

Multi-Sensor Design,

With Optional Mitutoyo QV-Index Unit

Model: QVTI-X404PIL-D S/N: 62456041

Code No. 364-180SZ New: 2016

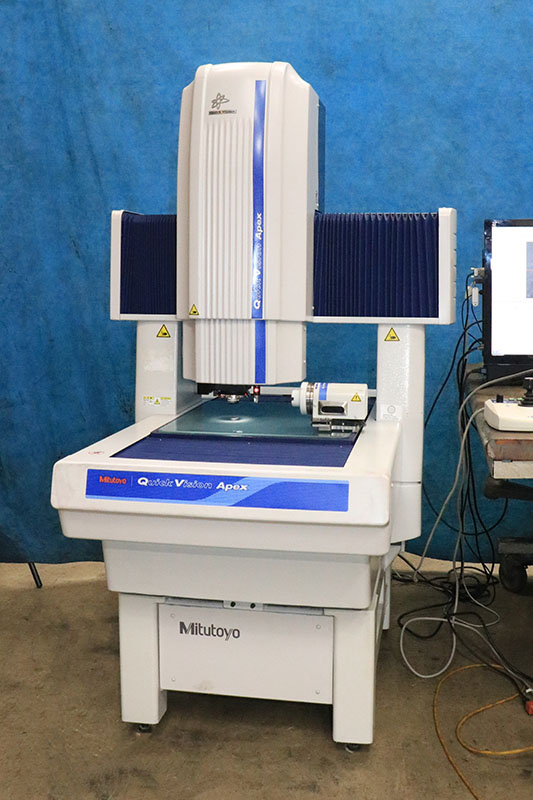

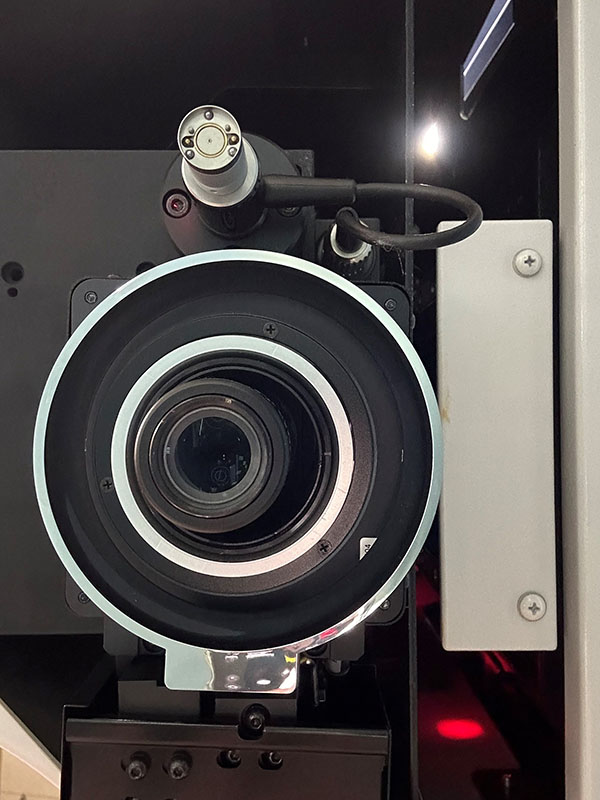

"The Quick Vision is a non-contact

dimension measurement system. It uses

its camera to take images magnified by

its optical lens and then uses image

processing technology to detect the

edges of the workpiece. Structural

deformation caused by movement

along each axis has been minimized,

ensuring the Quick Vision Series

performs highly accurate measurements

with minimal spatial coordinate

distortions."

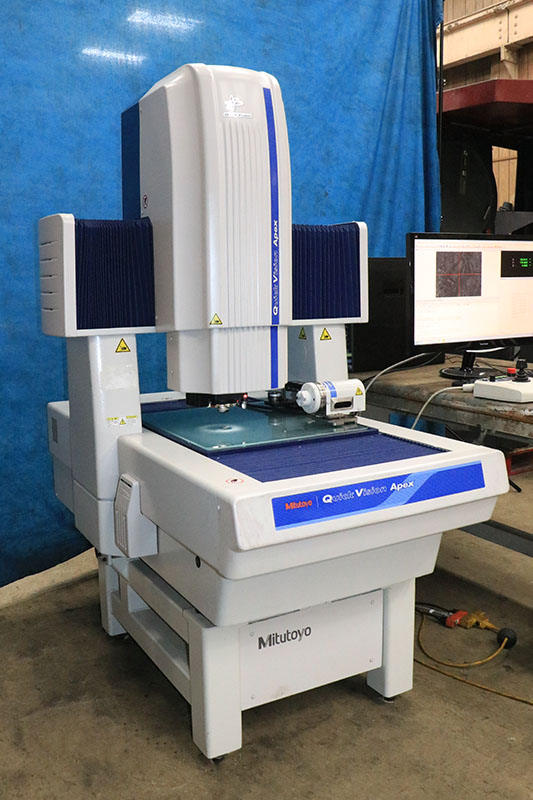

• Quick Vision Systems use LEDs for all

of their light sources: contour, surface,

and programmable ring light.

• Lighting uniformity is achieved at a

high level which leads to excellent

part program compatibility between

multiple QVs.

• LED light sources boast excellent

responsiveness which improves measurement

throughput.

• LED light sources have a longer life

expectancy than halogen types and reduce

illumination fluctuations, thereby

minimizing any errors

caused by changes in light intensity.

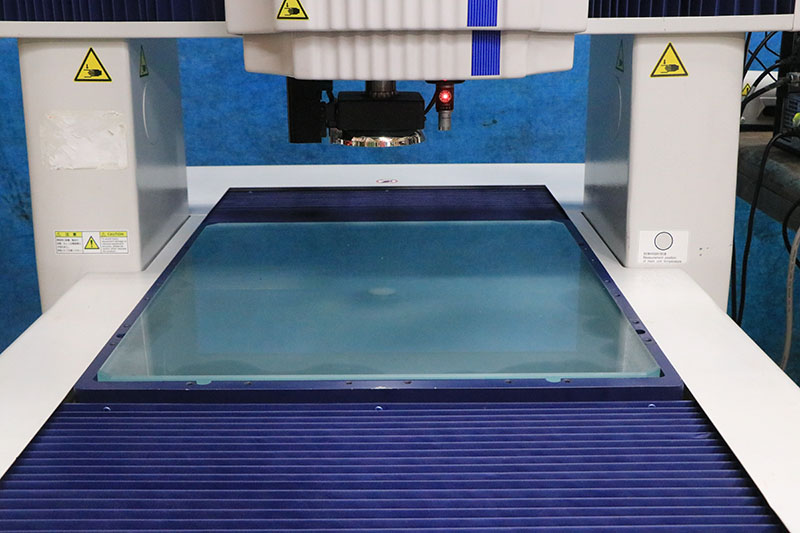

• The Quick Vision uses its optical system

to greatly magnify images to measure

dimensions.

• Because the Quick Vision performs

non-contact measurements, there is no

risk of the workpiece

being damaged, deformed or stained.

• The Quick Vision performs high-speed

measurements of multiple points within

the captured image. The image processing

technology a and high-speed stage

control enable high-throughput m

measurements.

• The Quick Vision Series uses its

image auto focus.

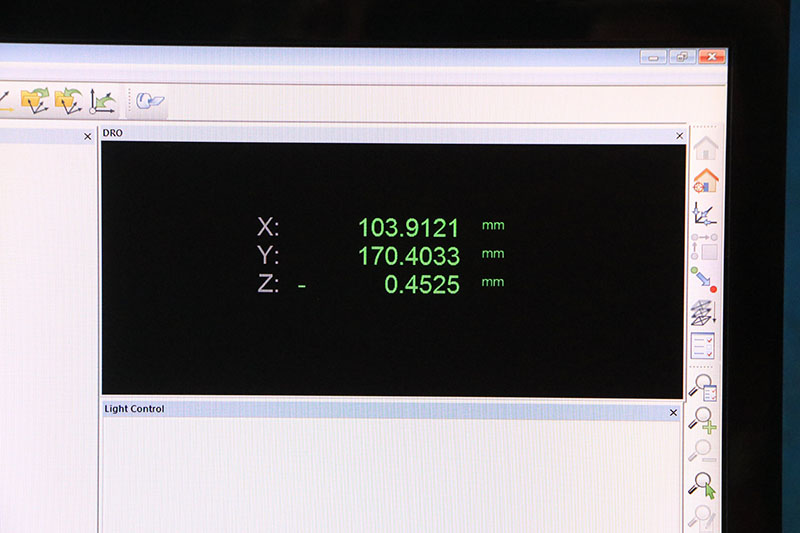

Measuring Range (X x Y x Z):

15.75″ x 15.75″ x 9.84″

(400mm x 400mm x 250mm)

X & Y Axes, Drive Speeds to 15.7" Per Second

Resolution of Scale: 0.1 μm Linear Encoder

Observation Unit Type: Zoom (8 Positions)

Image Sensor: Color CMOS Camera Illumination Unit

Co-Axial Light: White LED

Transmitted Light: White LED

PRL: 4-Quadrant Fixed White LED

Accuracy

E1x, E1Y: (1.5+3L/1000) μm

E1Z: (1.5+4L/1000) μm

E2: (2+4L/1000) μm

Observation Unit Std: 1X-2X-6X

Accuracy Guaranteed Temperature Range: 20±1°C

Size of Stage Glass: 19.41″ x 21.69″

(493mm x 551mm)

Maximum Stage Loading: 88lbs

Dimensions: 55.39″ x 40.43″ x 54.37″

Weight: 1,276 lbs.

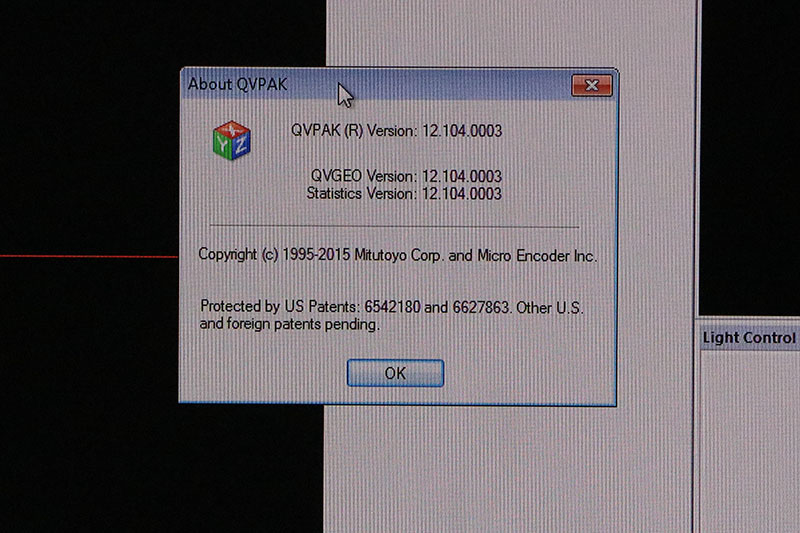

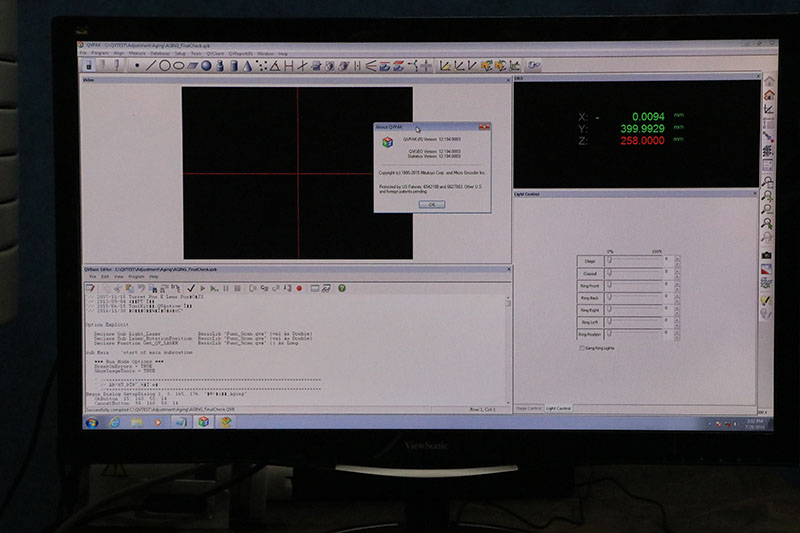

Equipped With:

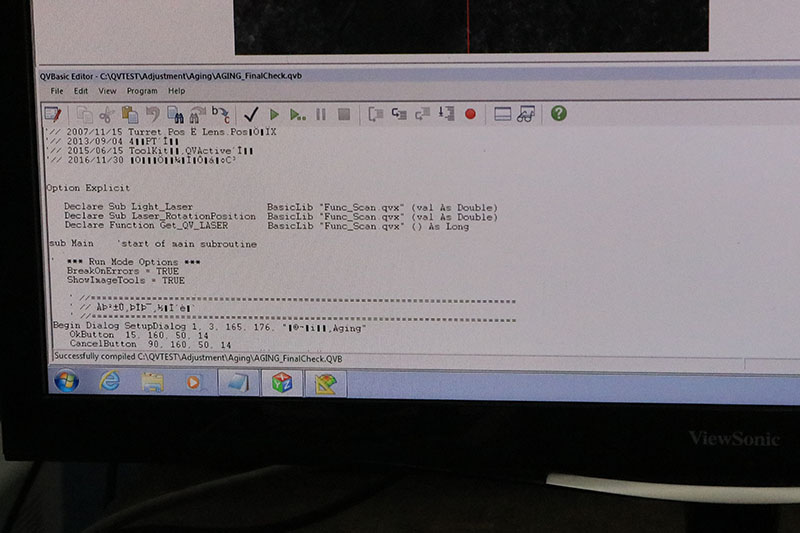

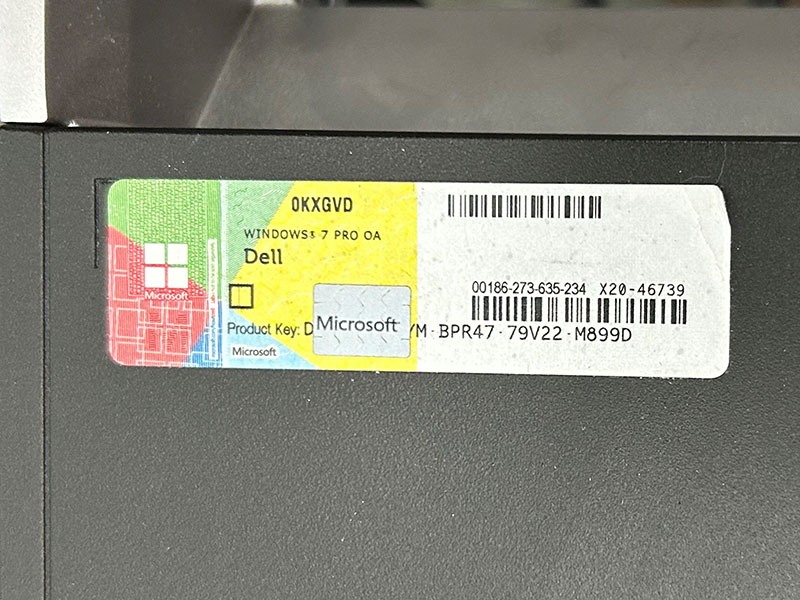

Dell Computer

Windows 7 PRO OS

Mitutoyo Software, QVPAK Version 12

High-Performance Multi Autofocus

"The QV Series is equipped with a

high-performance standard image autofocus

function. Image autofocus is used to assure

high accuracy measurement. Thanks to the

availability of various autofocus tools,

the optimal focus for each surface texture

and measured feature can be selected

which makes it possible to perform highly

reliable height measurements. Furthermore,

the autofocus operates at high speed,

increasing total measurement throughput."

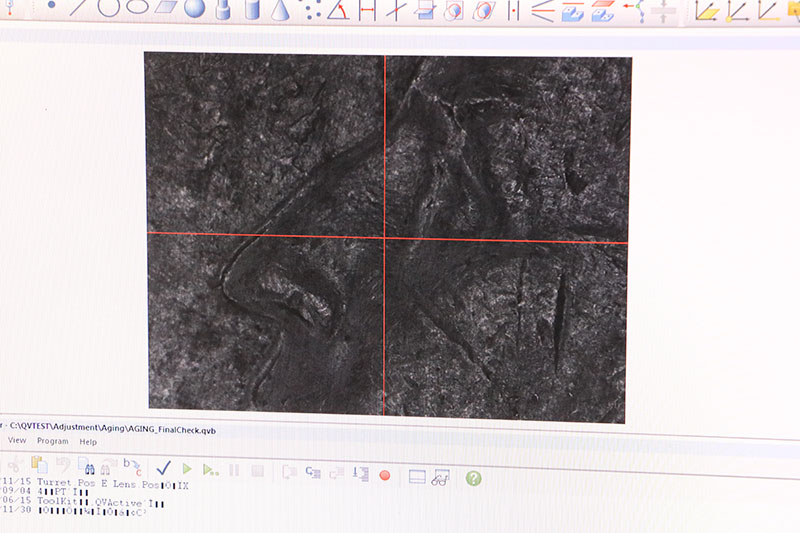

Magnified Vision

"A magnified image is captured by a camera

upon which dimensional measurements can be

produced using automated edge detection,

autofocus and image processing technology."

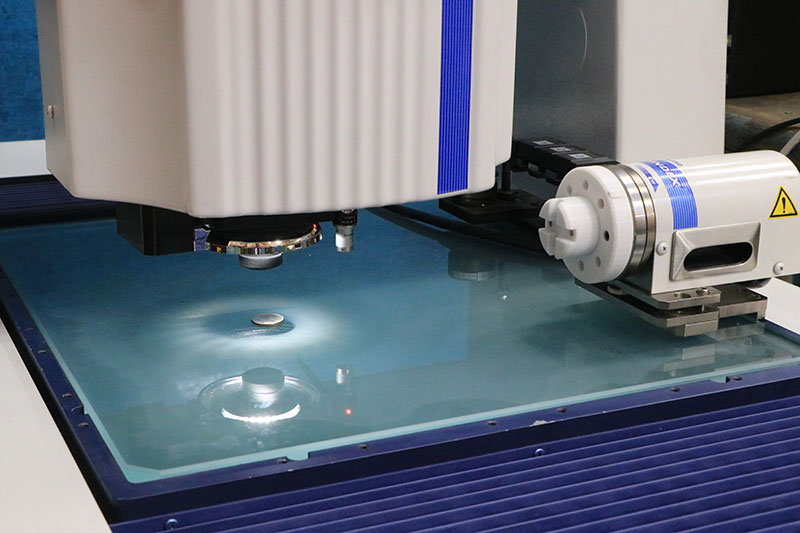

Renishaw Probe Head, Uses a TP-20 Stylus

"Quick Vision Series can also support

touch-trigger probes to provide measurement

of workpiece features that cannot be

inspected with vision alone. This capability

is also useful when extremely precise height

measurement is required."

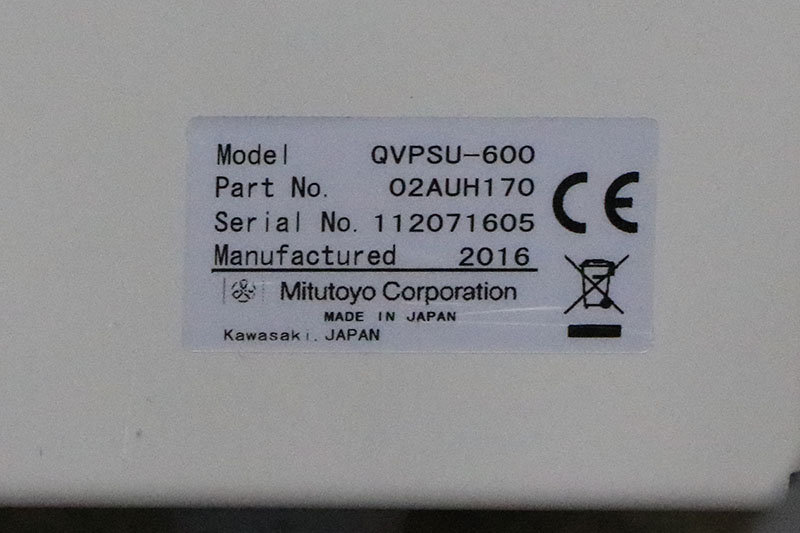

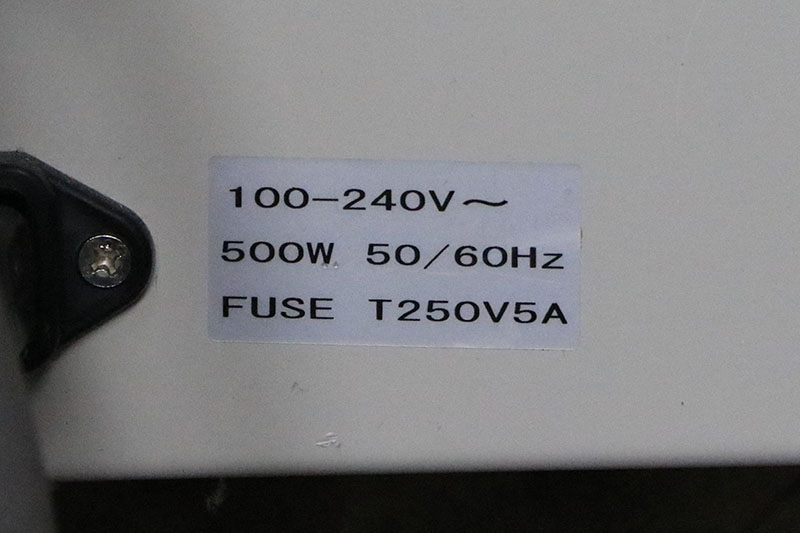

Mitutoyo QVPSU-600 Power Supply Unit

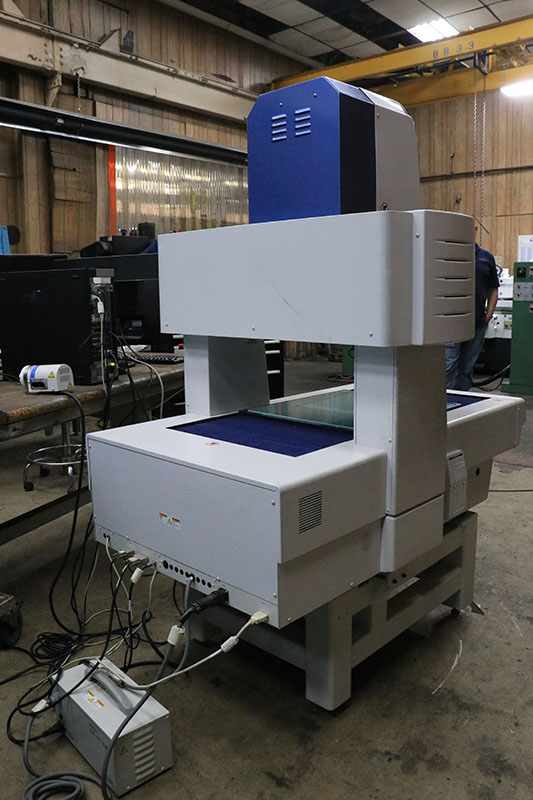

Mitutoyo QV-INDEX CNC Unit,

Option No. 363-002A, S/N: 100351602 .

"Using the QV index to rotate the workpiece

makes it possible to automatically measure

multiple surfaces without having to

reorientate the workpiece."

Multi-Function Control Box, Variable Speed

Control, Joystick, E-Stop Button & 4-Digit

Staus LED.

"Tracking Focus" Feature, Function that allows

Continuous Focusing in Response to Change

in Workpiece Height. Improves Measurement

Throuput.

Shipping Brackets

** Superior Condition - Serviced by Mitutoyo on

06/25/2024 **

** In Stock, Available for Immediate Delivery

from our Harrison, NJ Warehouse **