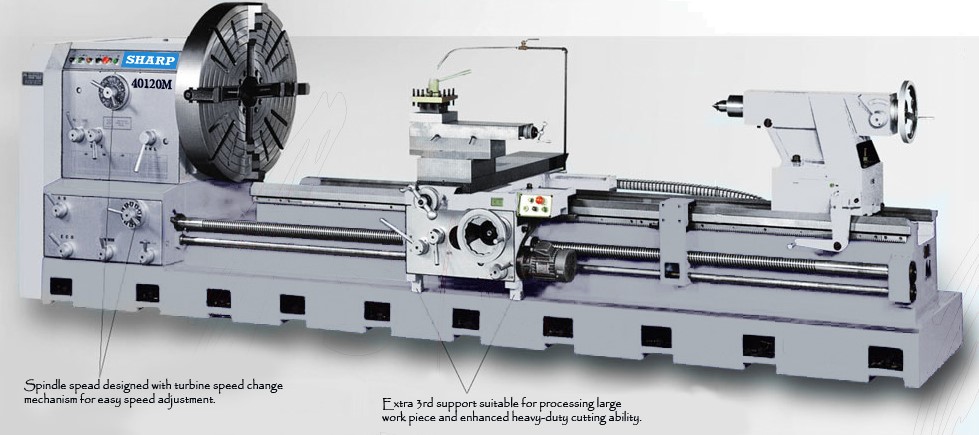

NEW 34" x 120" SHARP BIG BORE LATHE

MODEL: 34120M (20”) LATHE

SPECIFICATION:

CAPACITY

SWING OVER BED .................. 33.85”

SWING OVER CROSS SLIDE .......... 21.25”

DISTANCE BETWEEN CENTERS ........ 118.1”

BED

SWING OVER GAP .................. 47.22”

WIDTH OF BED .................... 20”

WIDTH OF GAP (SPINDLE END FACE).. 9.45”

LENGTH OF BED ................... 208.7”

HEADSTOCK

SPINDLE BORE DIAMETER ........... 6”

NUMBERED OF SPINDLE SPEEDS ...... 12 STEPS

RANGE OF SPINDLE SPEEDS ......... 16-810 R.P.M.

SPINDLE NOSE .................... A2-11

CARRIAGE

WIDTH OF CARRIAGE ............... 26”

CROSS SLIDE TRAVEL .............. 20.08”

COMPOUND REST TRAVEL ............ 14.57”

MAX. SIZE CUTTING SIZE .......... 1.26” X 1.26”

TAILSTOCK

QUILL DIAMETER .................. 4.5”

QUILL TRAVEL .................... 11.8”

QUILL TAPER ..................... MT#6

THREADS

LEADSCREW DIAMETER & PITCH ...... 1.77” X 2 T.P. I.

RANGE OF METRIC PITCH ........... 65 NOS ( 0.8 -14 MM)

RANGE OF INCH PITCHES ........... 36 NOS (2- 28 TPI)

RANGE OF DIAMETRICAL PITCHES .... 36 NOS ( 4-56 DP)

RANGE OF MODULE PITCHES ......... 22 NOS ( 0.5 – 7 MP)

FEEDS

FEED ROD DIAMETER ............... 1.26”

RANGE OF LONGITUDINAL FEEDS ..... 0.0020” – 0.028” IN/REV

RANGE OF CROSS FEEDS ............ 0.0010” – 0.14” IN/REV

MOTOR

MAIN SPINDLE MOTOR .............. 20 HP

COOLANT PUMP MOTOR .............. 1/8 HP (0.1 KW)

RAPID MOTOR ¼ HP

GENERAL

MACHINE DIMENSION (L X W X H) ... 224” X 81” X 57.1”

MACHINE WEIGHT (APPROX.) ........ 19,360 LBS

STANDARD EQUIPMENT:

COOLANT DEVICE

X, Z – AXES AUTO LUBRICATION SYSTEM

METRIC/INCH GEAR BOX

COOLANT DEVICE

LONGITUDINAL ADJUSTABLE POSITION FEED STOP

TAILSTOCK , TWO STEPS DEVICE

3 JAW SCROLL CHUCK SC 12”

BACK PLATE OF CHUCK

X, Z – AXES WITH TURCITE-B

STEADY REST 11.5”, BEARING TYPE (GRIP RANGE 20-260 MM)

DEAD CENTER

CENTER SLEEVE MT#5

4 –WAY TOOL POST & TOOLPOST SCREW WRENCH

LEVEL PADS

TOOLS AND TOOL BOX

OPERATION MANUAL

SPINDLE MOTOR : 20 HP

FEATURES:

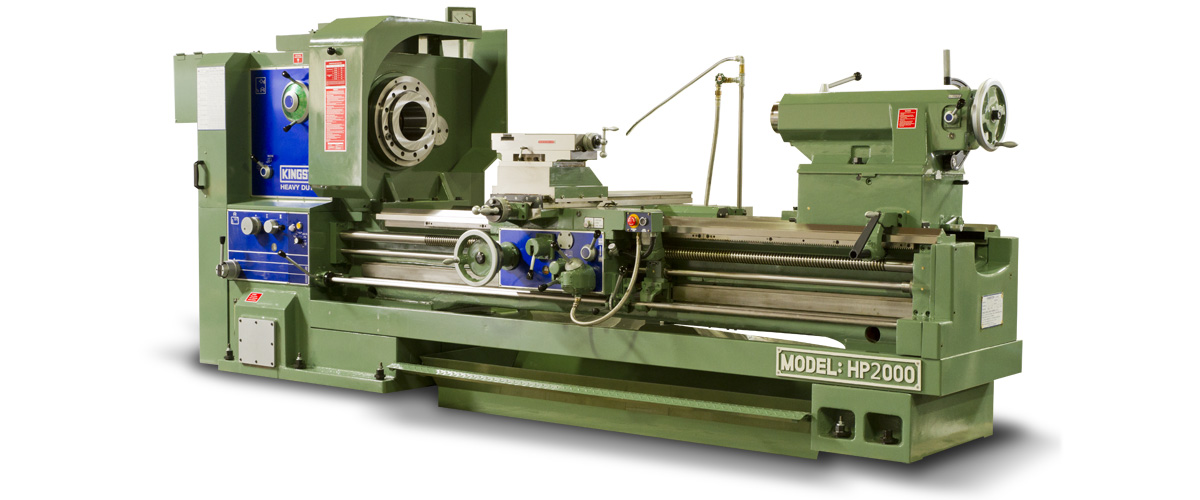

IT IS SUITABLE FOR TURNING AND CUTTING OF LARGE WORK PIECES AND STEEL ROD MATERIALS FOR HEAVY INDUSTRIES LIKE OIL PIPE NETWORK, AEROSPACE AND HEAVY-DUTY SHAFT PROCESSING.

1. CASTING:

1. ONE PIECE CASTING WORK WITH REINFORCED INNER STRUCTURE, EXTRA 3RD SUPPORT TO BE SUITABLE FOR PROCESSING OF LARGE WORK PIECE AND ENHANCED HEAVY-DUTY CUTTING ABILITY.

2. THE REMOVABLE GAP HAS BUILT IN REINFORCED STRUCTURE AND DOES NOT AFFECT ANY CUTTING STABILITY.

2. SPINDLE:

1. BORE 6 “, 16-STEP SPEED CHANGE, TURBINE SPEED CHANGE MECHANISM WITH NO EASY SPEED JUMPING AND THREE POINT SUPPORT FOR THE BOX.

2. FITTED WITH ADJUSTABLE, ELECTROMAGNETIC BRAKE FOR EASY BRAKING ADJUSTMENT ACCORDING TO DIFFERENT WORK PIECE MATERIALS AND SPEED.

3. GEAR AND SHAFT ARE MADE OF SUPER ALLOY MATERIAL WITH FAG BEARINGS TO OFFER DURABLE CUTTING AND LOW PRODUCTION NOISE.

4. SEALED OIL BATH LUBRICATION SYSTEM WITH ENFORCED OIL SUPPLY BY MECHANICAL PUMP TO ACHIEVE BETTER LUBRICATION EFFECTS.

3. GEAR BOX:

METRIC / INCH GEAR BOX FREE FROM GEAR EXCHANGE TO IMPROVE PRODUCTION EFFICIENCY. SPEEDY INSTALLATION, FORWARD AND REVERSE MOVEMENT, SAFETY INSTALLATION WITH AUTOMATIC SEALED OIL BATH LUBRICATION SYSTEM.

4. APRON FEEDING DEVICE:

SWIFT TRANSMISSION, POSITIVE AND NEGATIVE ROTATION MOVEMENT AND SAFETY DEVICE WITH AUTO SEALED OIL BATH LUBRICATION & CROSS RAPID FEEDING.

5. SADDLE:

ANTI-FRICTION PROCESSED SURFACE WITH REGULAR OIL INJECTION, LUBRICATED AND FRICTION ENDURABLE.

6. TAILSTOCK:

TWO STAGE IN-FEED DEVICE, SWING ARM MOVEMENT TO HAVE SMOOTH AND LABOR SAVING OPERATION.

7. ELECTRICAL CONTROL:

2 STAGE SAFETY START-UP DEVICE AND OVERLOADING POWER CUT SYSTEM.

8. CASTINGS:

FC-30 STEEL IS USED FOR MAIN STRUCTURES LIKE BASE, SPINDLE, SADDLE AND TAILSTOCK, WHICH ARE ANNEALED AND HAVE NO DEFORMATION.

9. PROCESSING:

BASE, SPINDLE, SADDLE, SLOT SURFACE OF TRAVELING PLATE, TOOL BASE SLIDING TABLE, TAIL SHAFT PIPE ARE HIGH FREQUENCY TREATED, PRECISION GROUND FOR EXTENDED SERVICE LIFE.

10. HEADSTOCK:

GEAR AND SHAFT ARE MADE OF SUPER ALLOY MATERIAL WITH FAG BEARINGS TO OFFER DURABLE CUTTING AND LOW PRODUCTION NOISE, TURBINE SPEED CHANGE MECHANISM WITH AN EASY SPEED JUMP. THREE POINT SUPPORT FOR THE BOX.

11. ELECTRIC BOX

2 STAGE SAFETY START-UP DEVICE, DURABLE CUTTING AND LOW PRODUCTION NOISE. OVERLOADNG POWER CUT SYSTEM, FILTERED WITH ADJUSTABLE , ELECTROMAGNETIC BRAKE FOR EASY BRAKING ADJUSTMENT ACCORDING TO DIFFERENT WORK PIECE MATERIALS AND SPEED.

OPTIONAL ACCESSORIES:

• FOLLOW REST, BRONZE JAWS ( GRIP RANGE 30 MM TO 150 MM)

• REAR CHUCK ADAPTER

• BACK SPLASH GUARD

• STEADY REST WITH BEARING 15” ( GRIP RANGE 170 - 370 MM)

• STEADY REST WITH BEARING 20” ( GRIP RANGE 220 - 480MM)

• STEADY REST WITH BEARING 24” ( GRIP RANGE 300 - 600 MM)

• TAPER ATTACHMENT( 450 MM TRAVEL, +/- 8 DEGREES)

• 3-JAW STRONG SCROLL CHUCK SK -16” ( 160 MM BORE), A2-11 WITH BACK PLATE , ID RANGE 110-360 MM. OD: 30-380 MM

• 4-JAW INDEPENDENT CHUCK, CAST IRON A2-11-20” ( 160 MM BORE) MADE IN CHINA

• 4-JAW INDEPENDENT CHUCK, A2-11-25” (DIRECT MOUNTED TYPE, 180 MM BORE) MADE IN CHINA

• HALOGEN LIGHT

• FAGOR 20 I DRO FOR 2 X

• NEWALL NMS 800 DRO FOR 2 X

• DRO INSTALLATION