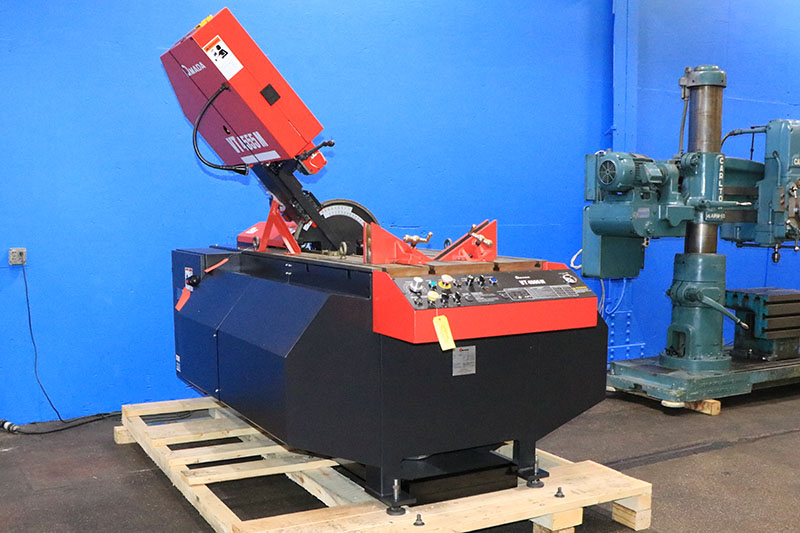

NEW AMADA-MARVEL TILT FRAME VERTICAL BANDSAW

MODEL: VT5063SW

SPECIFICATIONS:

CUTTING CAPACITY

ROUND (DIAMETER)

AT 0° .......................... 20.0″ (508 MM)

AT 45° ......................... 17.0″ (432 MM)

AT 60° ......................... 11.25″ (286 MM)

RECTANGLE (W X H)

AT 0° .......................... 20.0″ X 25.0″ (508 X 635 MM)

AT 45° ......................... 20.0″ X 17.0″ (508 X 432 MM)

AT 60° ......................... 20.0″ X 11.25″ (508 X 286 MM)

MAXIMUM VISE OPENING ........... 20.25″ (514 MM)

WORK LOAD CAPACITY ............. 8,000 LBS (3,628 KG)

SAW BLADE DIMENSIONS (L X T X W) 18′2″X0.050″X1-1/2″ (5537 X 1.3 X 41 MM)

BLADE SPEED 30-500 FT./MIN BY INVERTER 9-152 M/MIN BY INVERTER

TENSION CONTROL HYDRAULIC

BLADE CONTROL

CUTTING CONTROL DIRECT FORCE SENSING ELECTRIC BALL SCREW

WITH PC3 PROGRAMMABLE CONTROL

BLADE FEED FORCE 0 TO 300 LBS 0 TO 1334 N

VISE OPERATION

TYPE MAIN VISE (OPTIONAL SECOND VISE IS AVAILABLE TO INSTALL)

CONTROL HYDRAULIC, FULL STROKING WITH 9-12″ HIGH X 15″ WIDE 60° FACEPLATES

MOTORS

SAW BLADE ...................... 10 HP

HYDRAULIC PUMP ................. 5 HP (3.7 KW)

CUTTING FLUID PUMP ............. 1/8 HP (0.1 KW)

TILT GEAR ...................... 1/15 HP (0.05 KW)

POWER REQUIREMENT

POWER SUPPLY VOLTAGE AC230V±10% OR AC460V±10%, 3 PH, 60 HZ

VOLTAGE MUST BE MUST BE SPECIFIED WHEN ORDERING

CUTTING FLUID

TANK CAPACITY 60 GAL 227 LITERS

PUMP TYPE ELECTRIC: HYDRAULIC

TANK CAPACITY .................. 10 GAL 38 LITERS

MANUAL CHIP DISPOSAL

STANDARD FEED VISE

INDEX MECHANISM SHUTTLE VISE

MATERIAL INDEX AC SERVO MOTOR AND BALL SCREW

FEED STROKE 48″ 1219 MM

REMNANT LENGTH 23″ PLUS LENGTH OF PARTS 584 MM PLUS LENGTH OF PARTS

OPTIONAL SHUTTLE TABLE

FEED MECHANISM AUTOMATIC SERVO DRIVE INDEX WITH LINEAR GUIDE SYSTEM

FEED STROKE 8, 13 AND 18FT (IT MUST BE SPECIFIED WHEN ORDERING)

2438, 3962 AND 5486MM (IT MUST BE SPECIFIED WHEN ORDERING)

FEATURES

TILTING COLUMN

FOR MITER CUTTING UP TO 60° LEFT AND RIGHT OF VERTICAL. NOW WITH ELECTRONIC TILT, THE COLUMN IS ELECTRICALLY POWERED WITH ENCODER FEEDBACK AND PC3 TOUCH SCREEN CONTROLLER FOR PRECISION MITER POSITIONING.

0° – 3° CANTED COLUMN

STANDARD 3° FORWARD APPROACH ANGLE, FOR INCREASED EFFICIENCY IN THE CUTTING OF STRUCTURAL MATERIALS.

BLADE GUIDE

PATENT-PENDING ROTATING EASY LOAD COMBINATION CARBIDE AND BALL BEARING ROLLER GUIDES WITH SELF-TENSIONING DESIGN.

UPPER BLADE GUIDE ARM

HYDRAULICALLY POSITIONED AND LOCKING, CONTROLLED BY A SELECTOR SWITCH AT THE OPERATOR’S STATION.

FLUSHING HOSE

WASHES CHIPS FROM HARD TO GET AT PLACES REDUCING CLEAN-UP TIME.

WORK-REST ROLLERS

TWO TURNED BALL-BEARING ROLLERS, ONE ON THE ENTRY SIDE AND ONE ON THE DISCHARGE SIDE OF THE MACHINE BED.

VISES

HYDRAULIC, FULL STROKING WITH 9-1/2” HIGH X 15” WIDE 60° FACEPLATES. REMOVABLE FACE PLATES WITHOUT TOOLS TO ALLOW FOR BOTH MITERS AND 90° AT THE BLADE.

AUTOMATIC BAR FEED

THE PATENTED AUTOMATIC BAR FEED DESIGN FEATURES A 48″ STROKE LENGTH WITH INDEXING SPEEDS OF UP TO 60FPM. THE BAR FEED IS SERVO DRIVEN WITH ENCODER FEEDBACK, AND COMBINES PRECISION DOUBLE BALL SCREWS WITH PRELOADED RECIRCULATING LINEAR GUIDES, RESULTING IN POSITIONING ACCURACY OF +/- .005″ PER INDEX. OPTIONAL LONG-STROKE SHUTTLES.

PC3 PROGRAMMABLE CONTROL®

PROVIDES A PROGRAMMABLE LOGIC CONTROL UNIT WITH A 12” COLOR, TOUCH SCREEN DISPLAY. THE CONTROL FEATURES GRAPHICAL PART PROGRAMMING WITH MEMORY FOR UP TO 500 JOBS AND PARTS, AS WELL AS A MATERIAL SELECTION CHART AND CUSTOMIZABLE MATERIAL LIBRARY.

DESCRIPTION:

⦁ 10 HP

⦁ 1-1/2" BLADE

⦁ AUTOMATIC INDEXING

⦁ HEAVY-DUTY

⦁ HYDRAULIC

⦁ METAL CUTTING

⦁ HIGH-SPEED BANDSAW

⦁ PROGRAMMABLE CONTROL

⦁ SERVO SHUTTLE