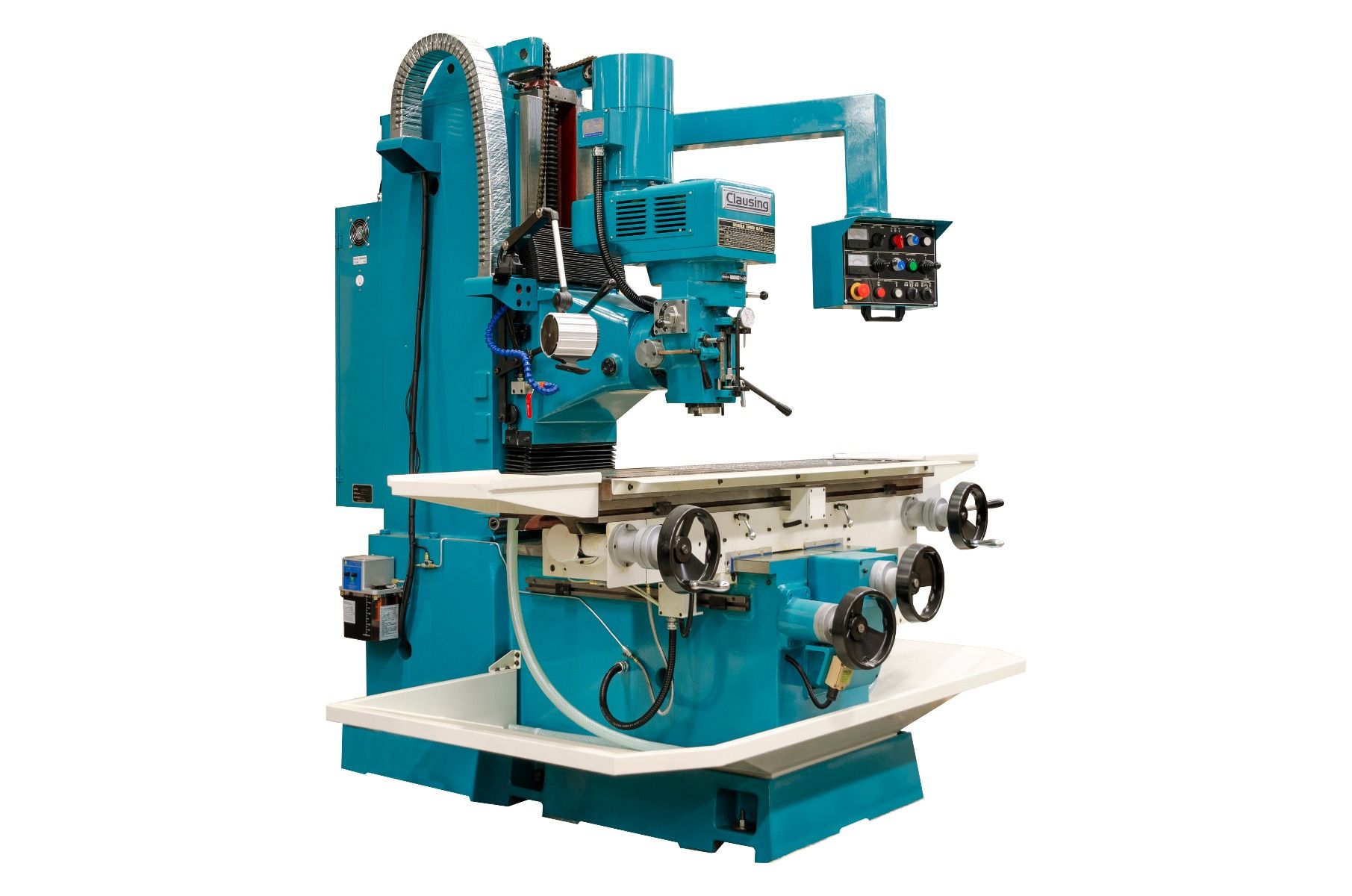

NEW CLAUSING HEAVY DUTY SUPER BED MILL

MODEL: SUP6BVS40

SPECIFICATIONS:

TABLE & WAYS

TABLE SIZE ........................ 15” X 60”

TABLE LOAD CAPACITY ............... 1,800 LBS.

NO. OF T-SLOTS .................... 3

T-SLOT WIDTH ...................... 0.709”

T-SLOT CENTER DISTANCE ............ 3.15”

TABLE WAYS (X AXIS) ............... DOVETAIL

BED WAYS (Y AXIS) ................. SQUARE

COLUMN WAYS (Z AXIS) .............. SQUARE

TRAVELS:

LONGITUDINAL (X AXIS) ............. 41.34”

CROSS (Y AXIS) .................... 19.69”

VERTICAL (Z AXIS) ................. 23.62”

QUILL DIAMETER .................... 4.13”

QUILL TRAVEL ...................... 5”

HEAD TILT (LEFT OR RIGHT) ......... 90◦

FEEDRATE X & Y AXES ............... 1.1 – 43.3 (IN/MIN)

FEEDRATE Z AXIS ................... 0.71-31 (IN/MIN)

X & Y AXES AC MOTOR WITH BRAKE .... 1 HP

Z AXIS AC MOTOR WITH BRAKE ........ ½ HP

MOTORS & SPINDLE:

SPINDLE MOTOR ..................... 5 HP (INVERTER VS)

SPINDLE SPEED (INFINITELY VARIABLE) 65-5160 RPM

NO. OF SPEED RANGES ............... 2

LOW GEAR RANGE .................... 65-590 RPM

HIGH GEAR RANGE ................... 575-5160 RPM

SPINDLE TAPER ..................... NMTB40

QUILL FEED (IN/REVOLUTION) ........ .0016/.003/.006

CONSTRUCTION:

HEIGHT ............................ 85.43”

WORKING WIDTH ..................... 92.91”

WORKING DEPTH ..................... 76.77”

WIDTH ACROSS COLUMN WAYS .......... 11.73”

LENGTH OF SADDLE ON BED ........... 25.98”

WIDTH ACROSS BED WAYS ............. 20.47”

SPINDLE NOSE TO TABLE ............. 3.93” – 27.55”

CENTER OF SPINDLE TO COLUMN WAYS .. 20.47”

FLOOR TO TABLE SURFACE ............ 37”

TABLE TO COLUMN WAYS (MIN/MAX) .... 2.05”/21.73”

BALL SCREW DIA./PITCH ............. 1.26”/.2”

BALL SCREW CLASS .................. C7

GROSS WEIGHT(APPROXIMATELY) ....... 6,600 LBS.

STANDARD EQUIPMENT

• POWERFUL 5 HP SPINDLE DRIVE MOTOR

• INVERTER VARIABLE SPEED DRIVE WITH 2 SPEED RANGES AND 2 MECHANICAL SPEED RANGES

• HARDENED AND GROUND SPINDLE WITH NMTB40 TAPER

• HARDENED AND CHROMED QUILL WITH 5” TRAVEL

• CP4 ABEC7 ANGULAR CONTACT SPINDLE BEARINGS

• C7 DOUBLE NUT X/Y/Z AXES 1.26” DIAMETER PRECISION BALLSCREW

• HARDENED AND GROUND TABLE SURFACE

• GROUND T-SLOTS TO PROVIDE ACCURATE REFERENCE EDGE

• HARDENED AND GROUND, SQUARE X/Y WAYS

• TURCITE B COATING ON SADDLE X/Y AXES WAYS

• MEEHANITE CASTINGS FOR SUPERIOR RIGIDITY AND WEAR RESISTANCE

• TELESCOPIC Z AXIS BALLSCREW COVER

• Z AXIS CONCERTINA ACCORDION WAY COVERS REDUCES OVERALL TRAVEL BY 50MM

• RUBBER Y REAR AXIS WAY COVERS

• STAINLESS STEEL FRONT AXIS WAY COVER

• COOLANT SYSTEM WITH PUMP

• LONG ARM HALOGEN WORK LIGHT

• TRANSFORMER

• AUTOMATIC LUBRICATION SYSTEM WITH ALARM

• TOOLS, TOOLBOX AND PARTS

STANDARD 230 3 PHASE (OTHER VOLTAGES REQUIRE A TRANSFORMER OR SPECIAL ORDER)

FEATURES AND BENEFITS:

CLAUSING BED MILL IS DRIVEN BY ELECTRONIC INVERTER VARIABLE SPEED DRIVE WITH V-BELT FROM MOTOR TO A SPINDLE PULLEY COUNTER SHAFT ASSEMBLY CAN ADJUST THE INFINITELY VARIABLE SPEED RANGE BY TURNING A DIAL. ELECTRICAL AND MECHANICAL HIGH/LOW SHIFT RANGES PROVIDE THE CORRECT TORQUE FOR YOUR MANUFACTURING APPLICATION. ONE OF THE HEAVIEST MILLS IN ITS CLASS, AND DESIGNED TO DELIVER ALL THE POWER, PRECISION, AND VERSATILITY YOU WILL NEED TO HANDLE MILLING JOBS IN YOUR MANUFACTURING FACILITY. COMBINED WITH AUTOMATIC LUBRICATION AND PENDANT CONTROLS THESE MACHINE ARE EASY TO MAINTAIN AND OPERATE.

THREE PHASE VOLTAGE REFERS TO THREE INDIVIDUAL LINES THAT CONNECT TO AND RUN VOLTAGE THROUGH THE MOTOR. EACH LINE ALTERNATES IN A SEQUENCE AS IT REACHES ITS VOLTAGE PEAK. THIS PROVIDES FOR A MORE STABLE FLOW OF VOLTAGE AND MORE HORSEPOWER TO THE MACHINE.