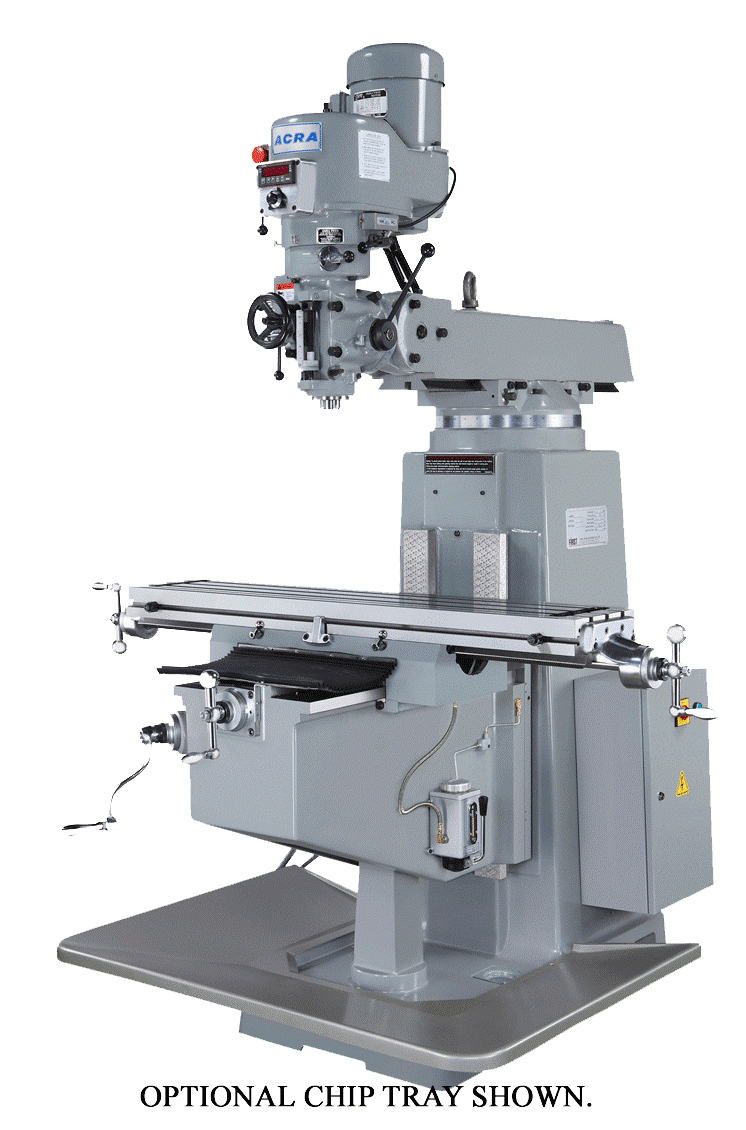

NEW GANESH PRECISION MILLING MACHINE

MODEL: GMV-2F

SPECIFICATIONS:

TABLE SIZE: ........................... 9” X 50” (230 X 1270 MM)

T-SLOT WIDTH / QUANTITY ................ 5/8” / 3 ON 2.5” CENTERS

TABLE LOAD CAPACITY..................... 440 POUNDS (200 KG)

TABLE LOAD CAPACITY, EVENLY DISTRIBUTED. 900 POUNDS (408 KG)

TABLE SURFACE TO FLOOR DIMENSION ....... 32’ – 48” (820 -1226 MM)

TABLE TRAVEL – LONGITUDINAL – X AXIS ... 38” (966 MM)

TABLE TRAVEL WITH POWER FEED ........... 33.07” (840 MM)

CROSS TRAVEL – Y AXIS .................. 12” (305 MM)

VERTICAL KNEE TRAVEL – Z AXIS .......... 16” (406 MM)

OVERARM (RAM) TRAVEL ................... 12” (305 MM)

OVERARM SWIVEL ........................ 360°

SPINDLE NOSE-TO-TABLE SURFACE .......... 0” – 18.5” (0 – 469 MM)

SPINDLE CENTERLINE TO COLUMN FACE ...... 6.75” – 18.75” (171 – 476 MM)

LEADSCREWS W/ GROUND PITCH SURFACE(X&Y). 0. 200” PER REV. (BALLSCREWS OPTIONAL)

ADJUSTABLE SCALE RING DISPLAY RESOLUTION 0.001” (5 MM)SPINDLE HEAD VARI-SPEED

SPINDLE MOTOR .......................... 3-HP, 3-PHASE 220 VAC

SPINDLE TAPER (HARDENED & GROUND) ...... R-8

SPINDLE RUNOUT ......................... 0.00008” MAXIMUM RUNOUT (0.002 MM)

SPINDLE BEARINGS ABEC-7 MATCHED SET .... CLASS-7 BEARINGS

VARIABLE SPEED SPINDLE ................. 60 – 4,500 RPM

HEAD TILT (LEFT-TO-RIGHT) .............. 90° – 0 – 90°

HEAD TILT (FRONT-TO-BACK / UP-DOWN) .... +45°– 0 – -38°

HEAD SWIVEL ON TURRET .................. 360°

QUILL DIAMETER ......................... 3-3/8” (85.725 MM)

QUILL TRAVEL – MANUAL & POWER FEED ..... 5” (127 MM)

QUILL FEEDS – W/ TRIP RELEASE - INCH ... 0.0015”, 0.003”, 0.006”

QUILL FEEDS – W/ TRIP RELEASE - METRIC . 0.04 MM, 0.08 MM, 0.16 MM

MACHINE WEIGHT ......................... 2,222 LBS. (1010 KGS)

MACHINE LAYOUT ......................... WIDTH –58” DEPTH – 63” – 75” HEIGHT -79”

ELECTRICAL REQUIREMENTS ................ 220 VAC, 3-PH., 60 HZ., 9.5 AMPS

FEATURES

• MEEHANITE CASTINGS, FINE GRAIN AND HIGH DENSITY CAST IRON USING THE SUPERIOR MEEHANITE PROCESS YIELDS SUPERIOR VIBRATION DAMPENING AND IMPROVED SURFACE FINISH AND TOOL LIFE

BED WAYS:

• HARD CHROME PLATING FOR X & Y AXES

• HARDENED AND GROUND DOVETAIL SLIDEWAYS IN X, Y, & Z

• HARDENED AND GROUND TABLE

SPINDLE:

• 3-HP VARIABLE SPEED HEAD FOR SUPERIOR METAL REMOVAL CAPABILITY

• SPINDLE SUPPORTED BY TWO PRECISION ANGULAR CONTACT AND ONE BALL-BEARING TO ENSURE RIGIDITY

• ABEC CLASS-7 MATCHED SUPER PRECISION SPINDLE BEARINGS

• SPINDLE RUNOUT 0.00008” MAXIMUM – GUARANTEED! (R8 SPINDLE)

• SPINDLE MADE FROM ONE-PIECE NI-CR ALLOY STEEL WITH INNER TAPER HARDENED AND GROUND

• HARDENED, GROUND AND POLISHED PRECISION BACK GEAR FOR QUIET SPINDLE OPERATION

• FORWARD/ REVERSE SWITCH HOUSED IN AN OIL-TIGHT SWITCH BOX

MILLING HEAD GEAR AND QUILL:

• POWER QUILL FEED WITH 3-FEEDS AND ADJUSTABLE FEED STOP & AUTOMATIC FEED TRIP RELEASE

• HARDENED AND GROUND QUILL – HARD CHROME PLATED AND POLISHED FOR A LONG SERVICE LIFE

• DYNAMICALLY BALANCE PULLEYS SUPPORTED IN PRECISION BEARINGS

MACHINE FEATURES:

• MULTIPLE KNEE AND TABLE LOCKS FOR SUPERIOR CUTTING RIGIDITY

• T-SLOTS GROUND TO 5/8” FOR AN ACCURATE REFERENCE EDGE - FITS STANDARD WORKHOLDING T-NUTS

• ONE-SHOT METERED CENTRAL LUBRICATION SYSTEM FOR SLIDEWAYS AND LEAD SCREWS

• WATER RESISTANT HALOGEN LAMP IS INCLUDED

• INSTRUCTION MANUAL, TOOLS AND TOOL BOX ALL INCLUDED

• LARGE COMPLIMENT OF PARTS AND ACCESSORIES IN STOCK TO ENSURE CONTINUED OPERATION