8" X 20" OKAMOTO "HIGH-PRECISION"

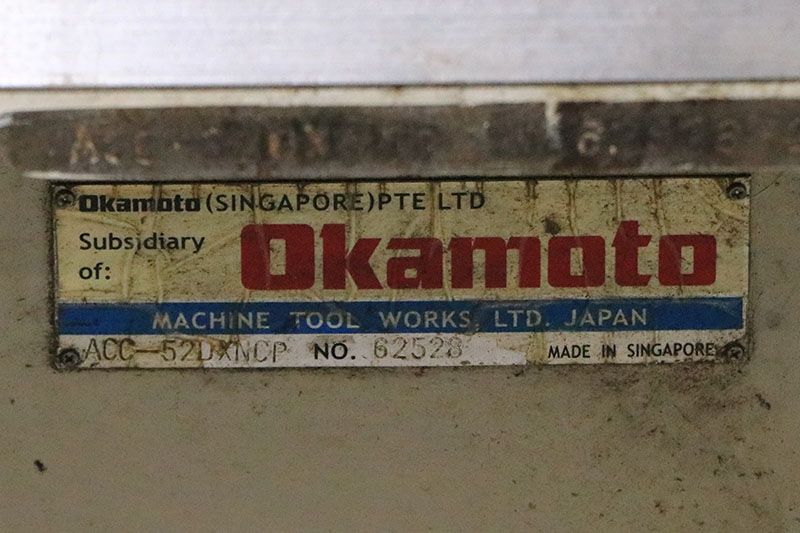

CNC PROFILE SURFACE GRINDER

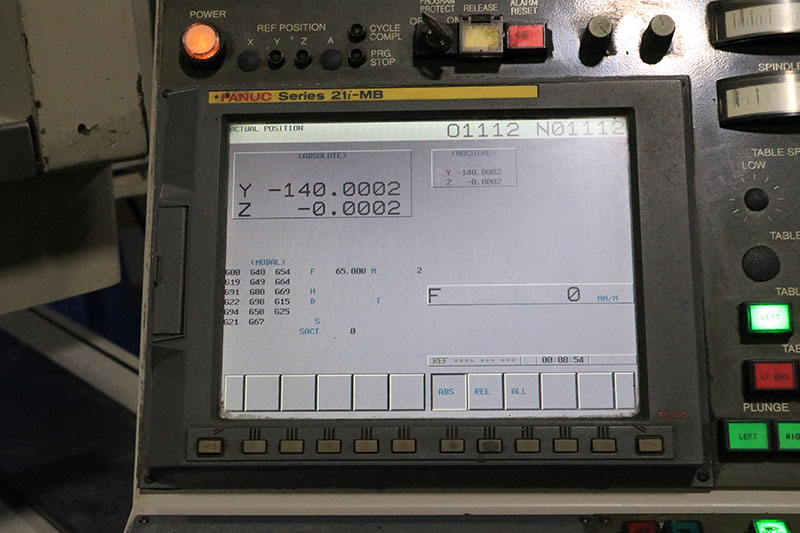

WITH “FANUC 21i-MB” CNC CONTROL

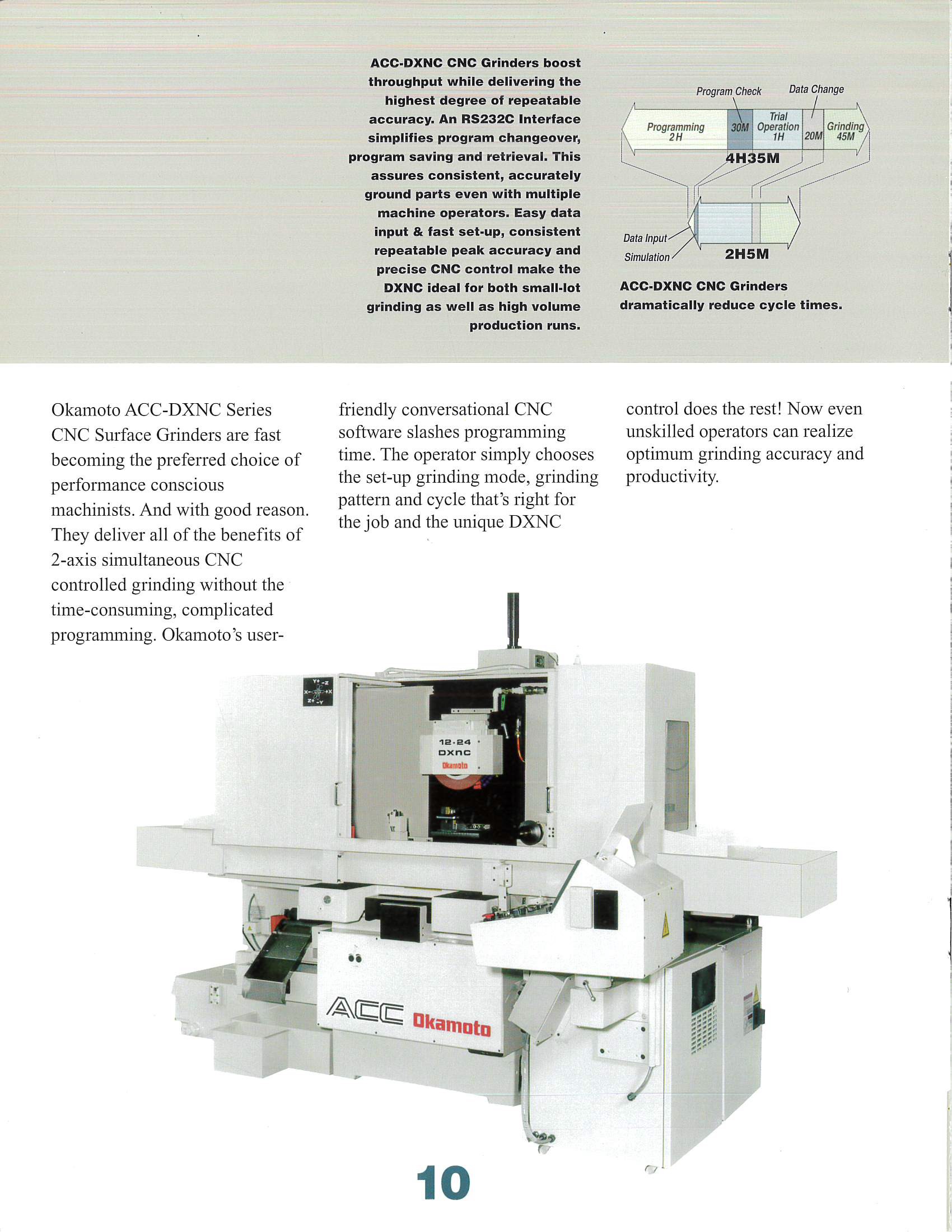

** Featuring Okamoto's User-Friendly Conversational

CNC Software. The Operator Simply Chooese the

Set-Up Grinding Mode, Grinding Pattern & Cycle

and the DXNC Does the Rest.

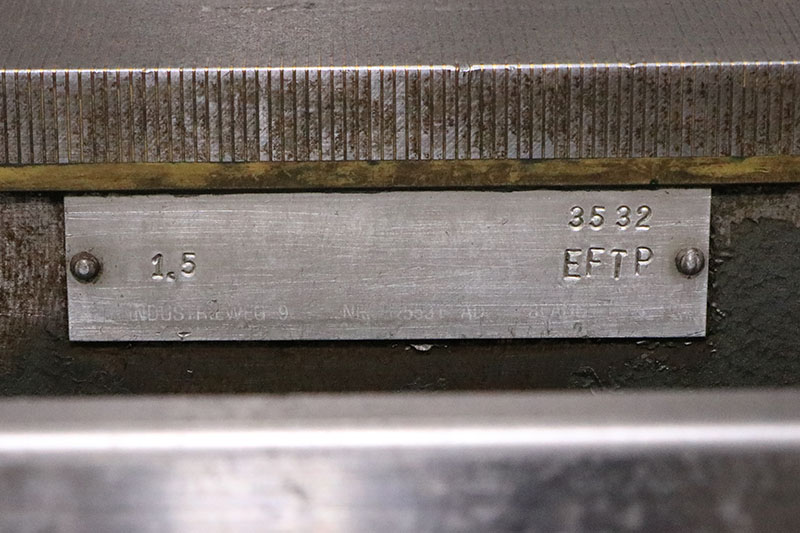

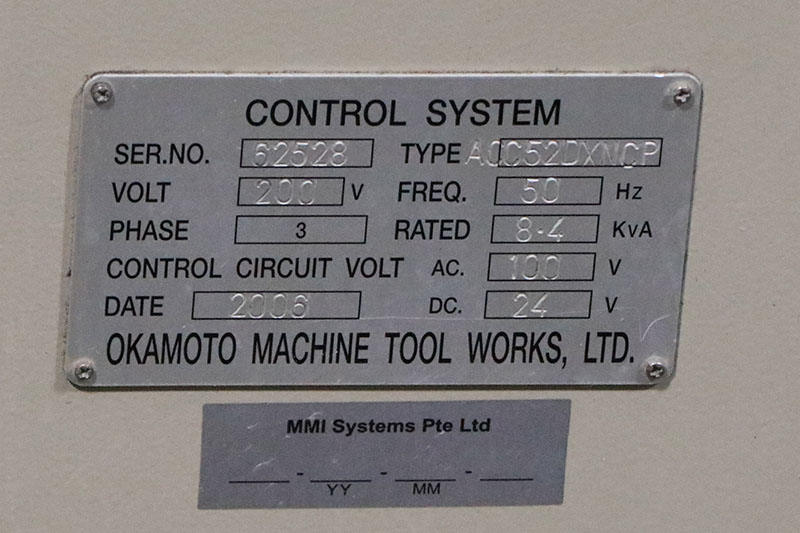

MODEL: ACC-820DXNC-P S/N: 62528 NEW: 2006

TABLE CAPACITY:

NOMINAL GRINDING CAPACITY ....... 8" x 20"

MAXIMUM HEIGHT UNDER 12" WHEEL .. 15.7"

LONGITUDINAL FEED (X AXIS):

TABLE SPEED, INF. VARIABLE ...... 3' TO 82' FPM

MAX. LONGITUDINAL TABLE

MOVEMENT, MANUAL ............... 25.6"

FEED PER HANDWHEEL REVOLUTION ... 1.85"

CROSSFEED (Z AXIS):

MAX. SADDLE TRAVEL .............. 9.0"

INTERMITTENT TRAVERSE FEED ..... 0.02" TO 0.40" IPM

GRINDING FEED ................... 0.010" TO 40" IPM

RAPID FEED ...................... 40" IPM

JOG FEED ........................ 0 TO 40" IPM

MANUAL PULSE GENERATOR ....... 0.00001", .0001", .001"

VERTICAL FEED (Y AXIS):

GRINDING FEED ................... 0.010" TO 40" IPM

INTERMITTENT DOWN FEED ......... 0.00001" TO 0.004"

SPEARKOUT PASSES ................ 0 to 5

RAPID FEED ...................... 40" IPM

JOG FEED ........................ 0 TO 40" IPM

MANUAL PULSE GENERATOR ....... 0.00001", .0001", .001"

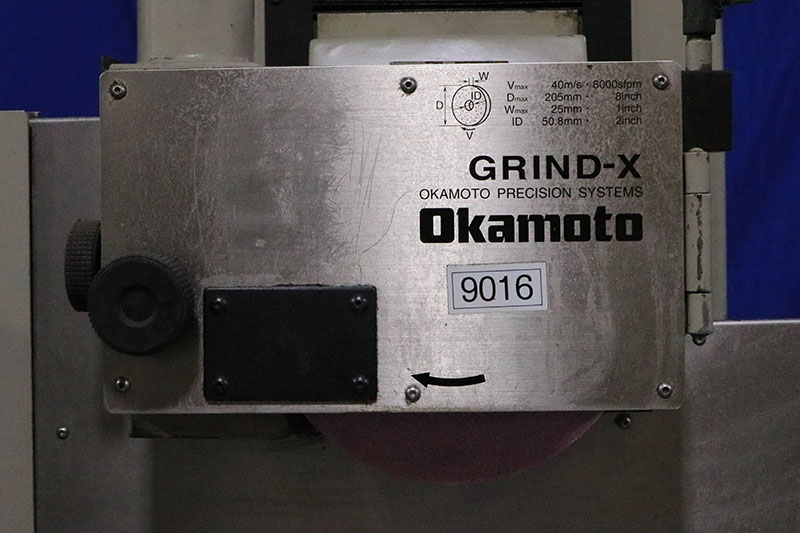

GRINDING WHEEL:

SPINDLE MOTOR ................... 1.5 KW, 2 H.P.

WHEEL SIZE ...................... 8"DIA. x 1"W x 1.25"B

SPEED ........................... 1,000 TO 3,600 RPM

APPROX. DIMS. FOR OPERATION ... 95" x 72"D x 97"H

APPROX. MACHINE WEIGHT .......... 4,630 LBS.

Programming Features

• Built-In Okamoto Conversational Programming System.

Featuring Okamoto's User-Friendly Conversational

CNC Software. The Operator Simply Chooese the

Set-Up Grinding Mode, Grinding Pattern & Cycle

and the DXNC Does the Rest.

With Intuitive Color Graphical Display.

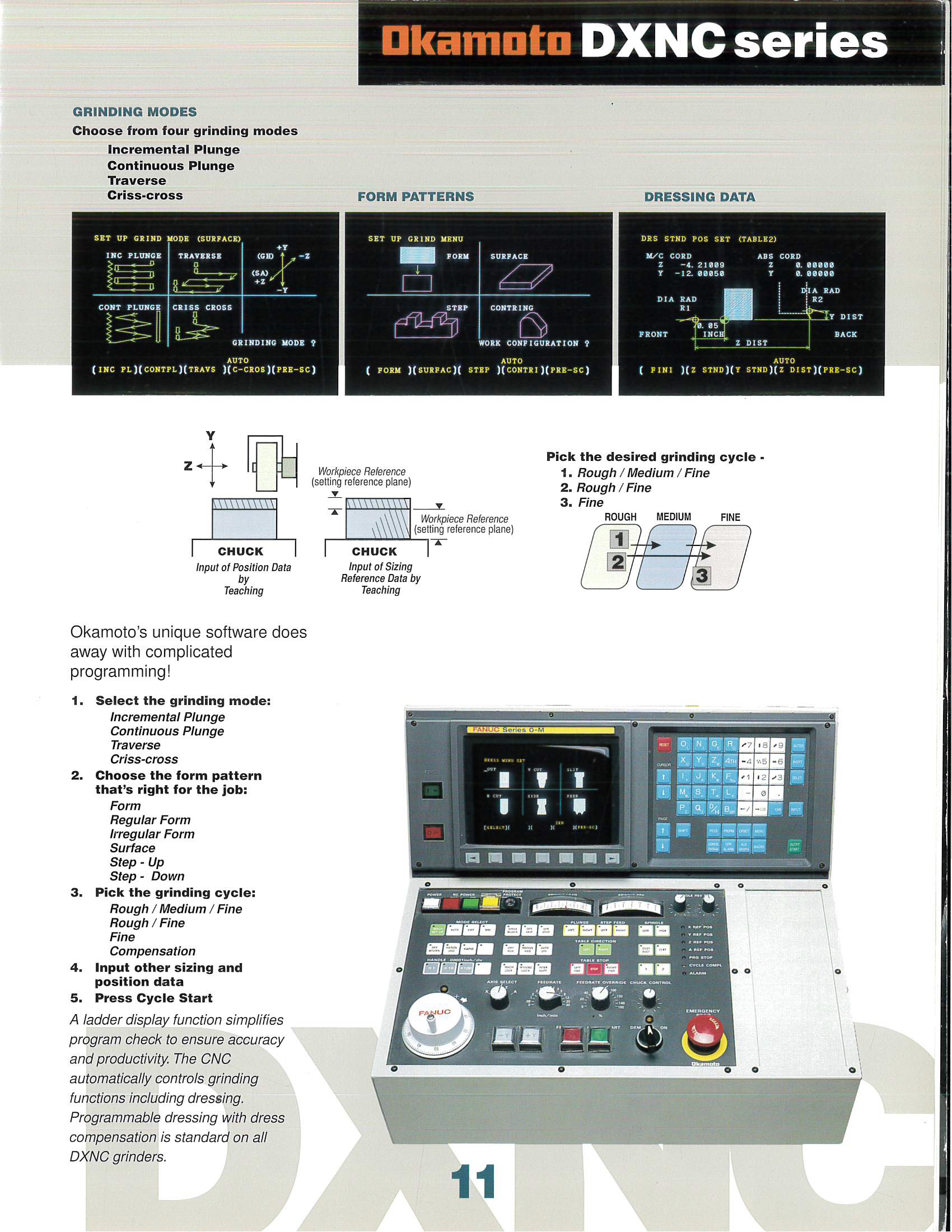

(1) Grinding Modes, Choose from Four Grinding Modes:

Incremental Plunge

Continuous Plunge

Traverse

Criss-Cross

(2) Choose the Form Pattern that's Right for the Job:

Form

regular Form

Irregular Form

Surface

Step-Up

Step-Down

(3) Pick the Grinding Cycle:

Rough/Medium/Fine

Rough/Fine

Fine

Compensation

(4) Input other Sizing & Position Data

(5) Press Cycle Start

• “Teach” Input Programming System ...

Operator simply moves the grinding wheel

manually to the grinding start position

and using an input key teaches that position

to the machine, then he moves the

wheel to the cross reversal position and

using the input key, teaches that position

to the machine, etc.

He then inputs stock removal, air cut,

dressing interval, etc., and the CNC control

automatically calculates total movement and

all start and stop points.

• “Drawing” Input Programming System ...

Input the actual dimensions from the workpiece

drawing and the control automatically

calculates the cycle sequence.

• Built-In Conversational Dress Programming ...

is based on the three basic types of dressing

menus -- “Side”, “R”, “V”, and “SLOT”.

“FREE” style may also be used utilizing

“G” and “M” Code programming.

All of the three basic types of dressing

menus have the capability to dress forms.

• Vertical & Cross Incremental Feed ...

with Multipliers of 0.00001”/0.0001”/0.001”.

Machine Features:

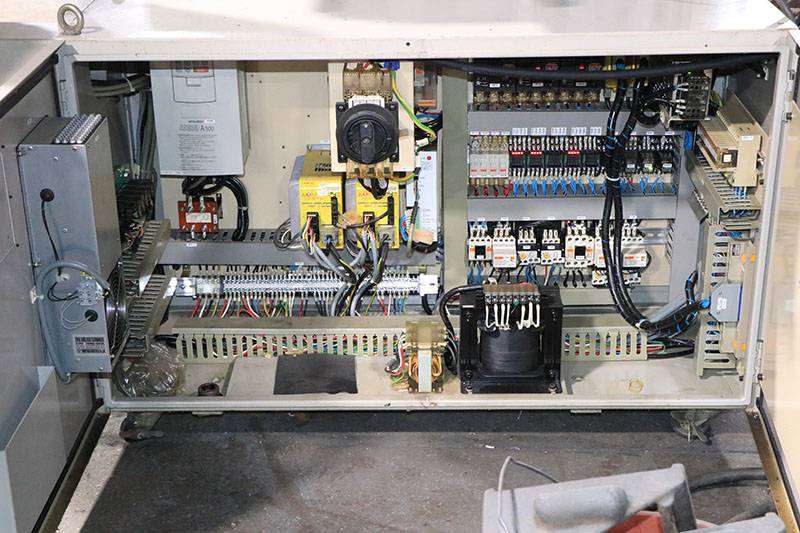

2-Axis Simultaneous CNC Controlled Grinding

Ball Screws, Fanuc AC Servo Drives, for the Cross & Vertical Axes

Hydraulic Table Traverse

Auto Lubrication System

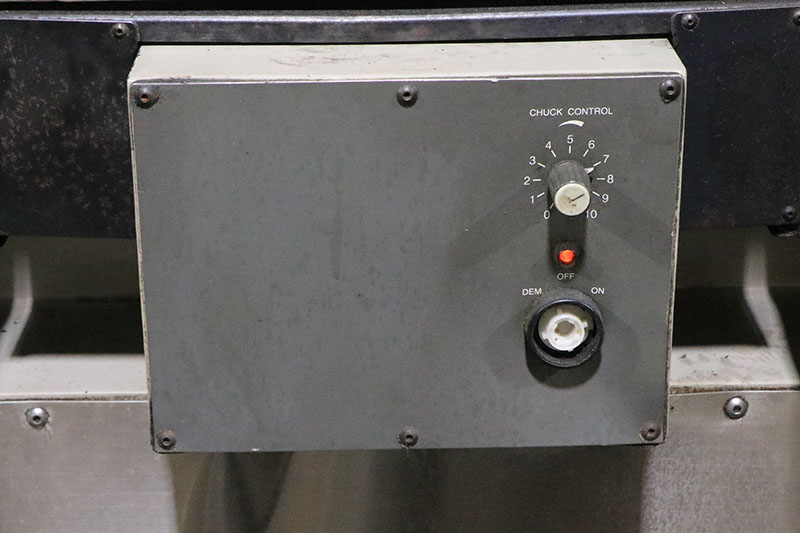

EQUIPPED WITH:

COOLANT SYSTEM

8" x 20" ULTRA FINE-DIVISION "CBP" ELECTRO-MAGNETIC CHUCK

VARIABLE HOLD NEUTROFIER CONTROL

MACHINE IS PRESENTLY WIRED FOR 3/60/200-220 VOLTS

** INSPECT UNDER POWER IN OUR HARRISON, NJ WAREHOUSE **

** EXCELLENT CONDITION & APPEARANCE **

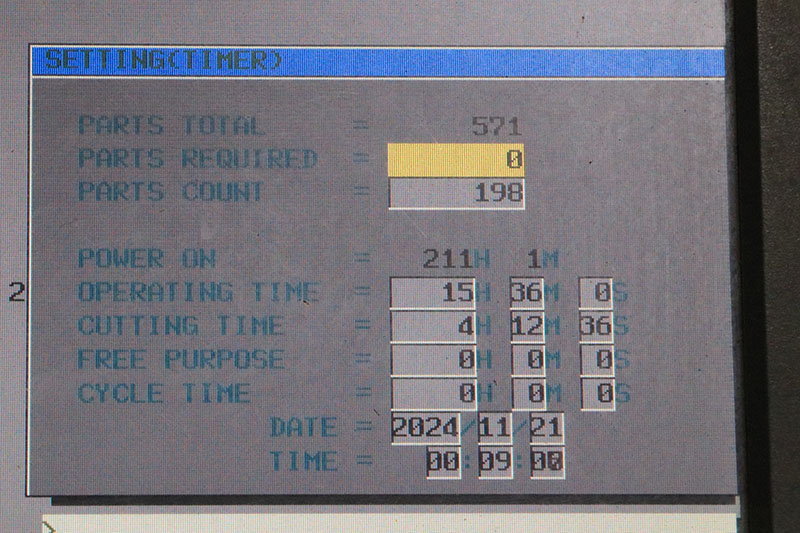

** - ALL ORIGINAL - LOW HOURS ON MACHINE **