12.6" X 20" OKAMOTO MODEL #OGM-820UNCB

CNC UNIVERSAL CYLINDRICAL GRINDER

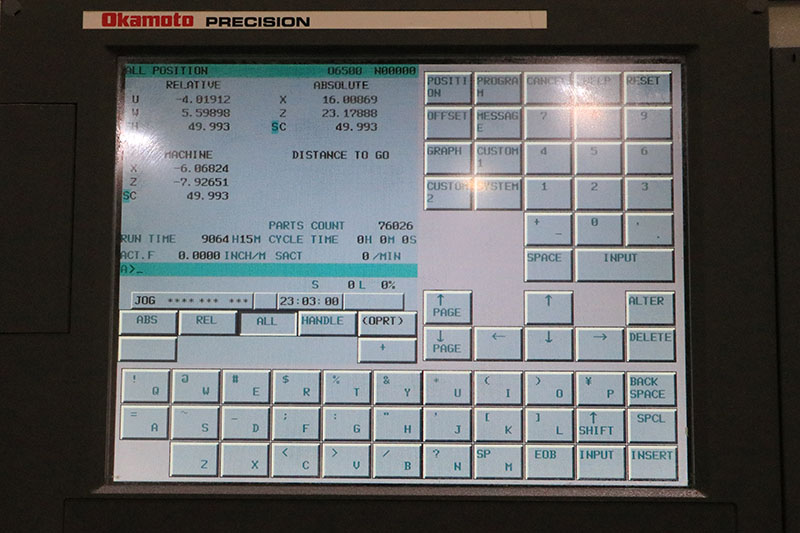

WITH FANUC OiTD CNC CONTROL,

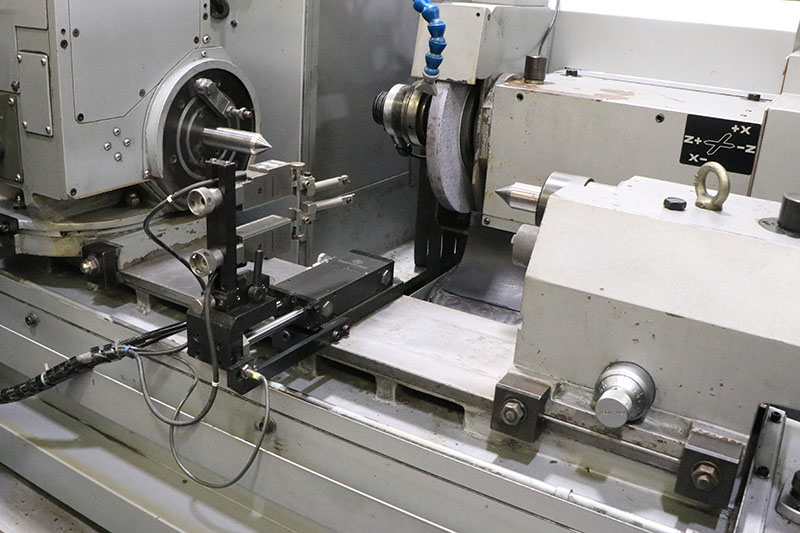

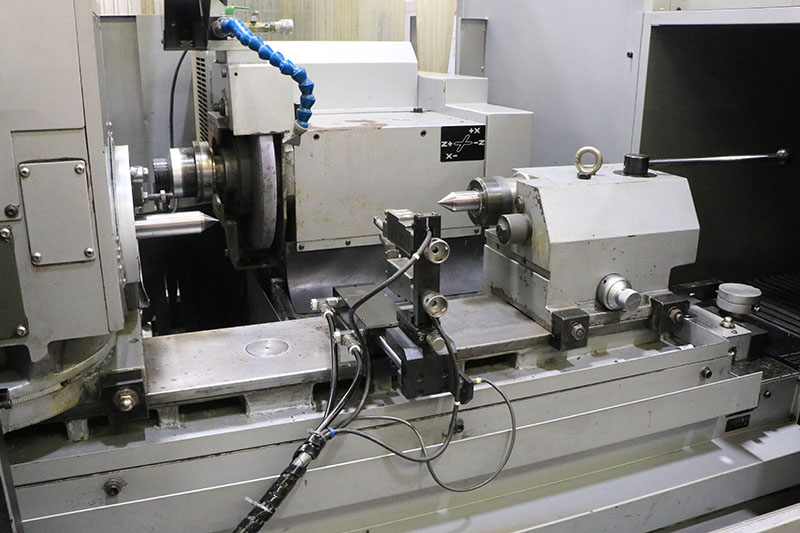

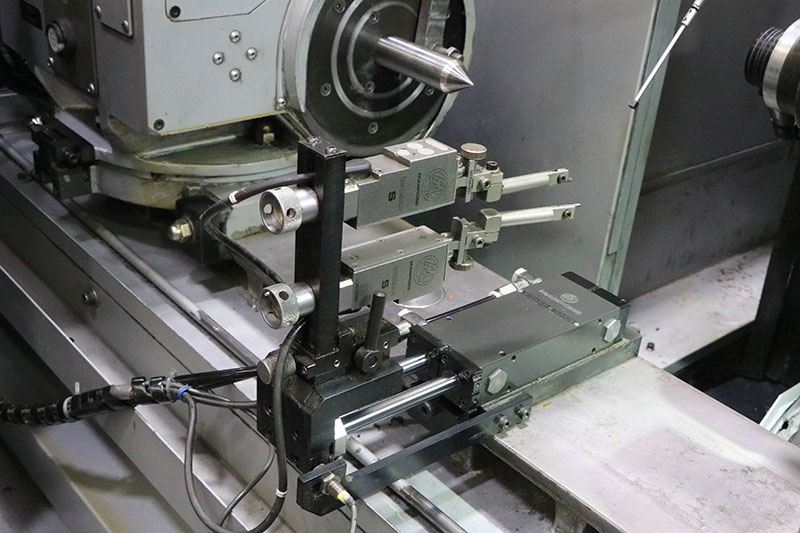

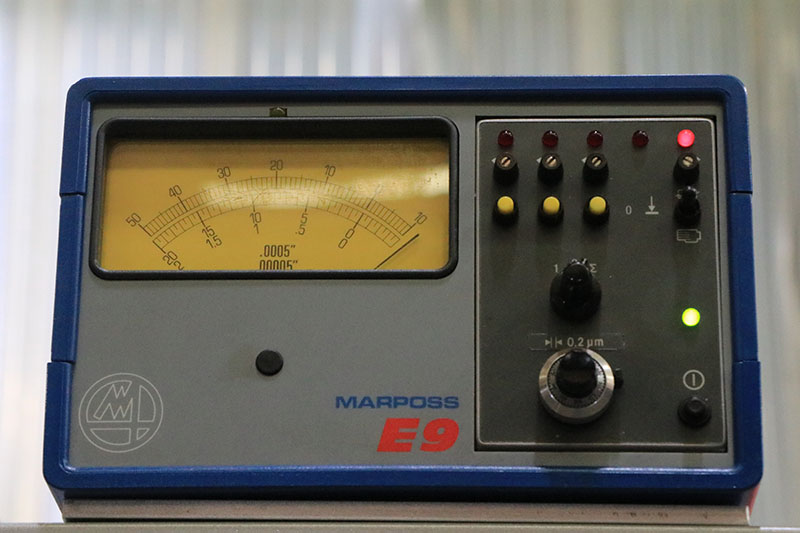

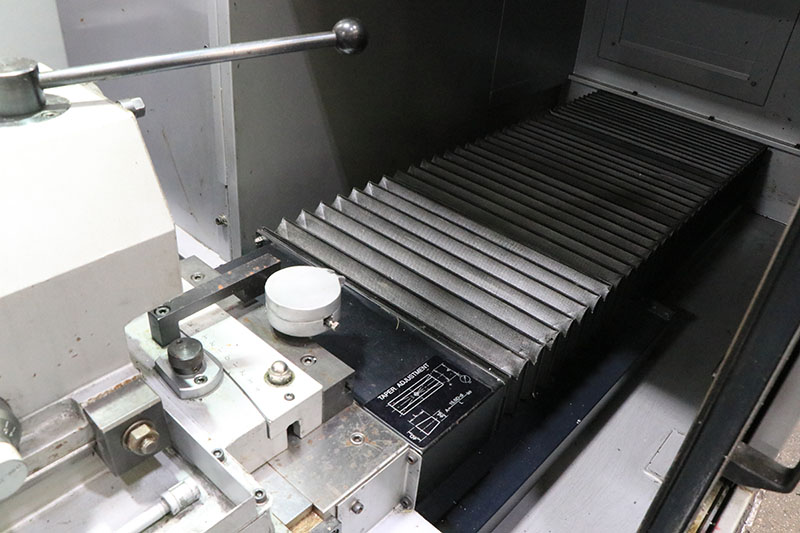

MARPOSS IN-PROCESS GAUGING,

SBS AUTO WHEEL BALANCING,

LATERAL LOCATOR, AND MORE!

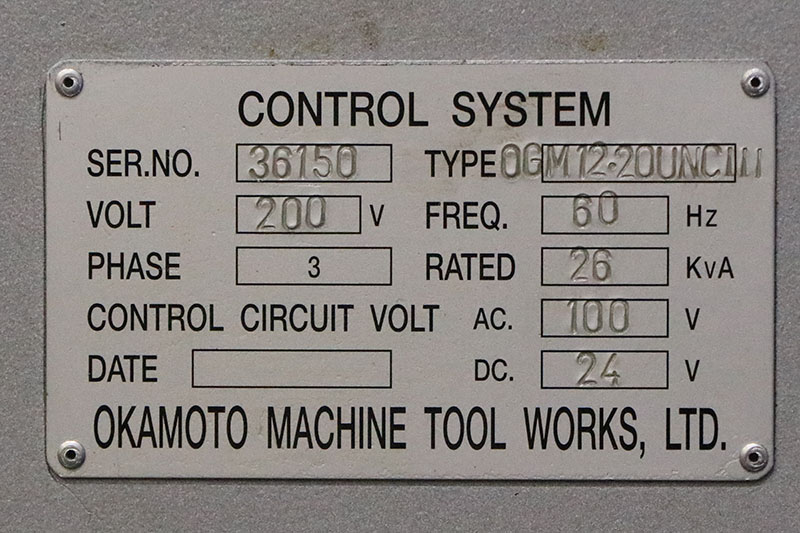

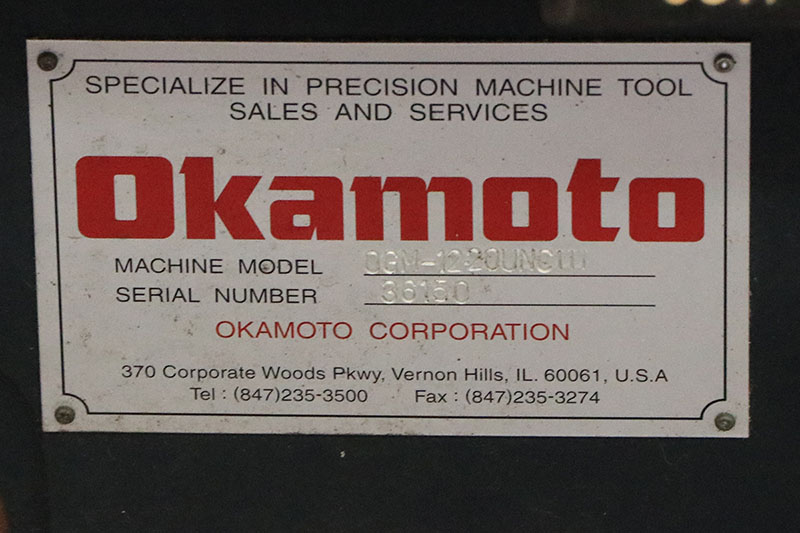

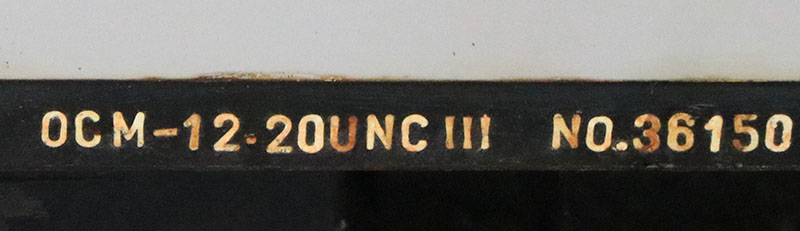

Model: OGM-12.20UNCIII S/N: 36150 New: 2013

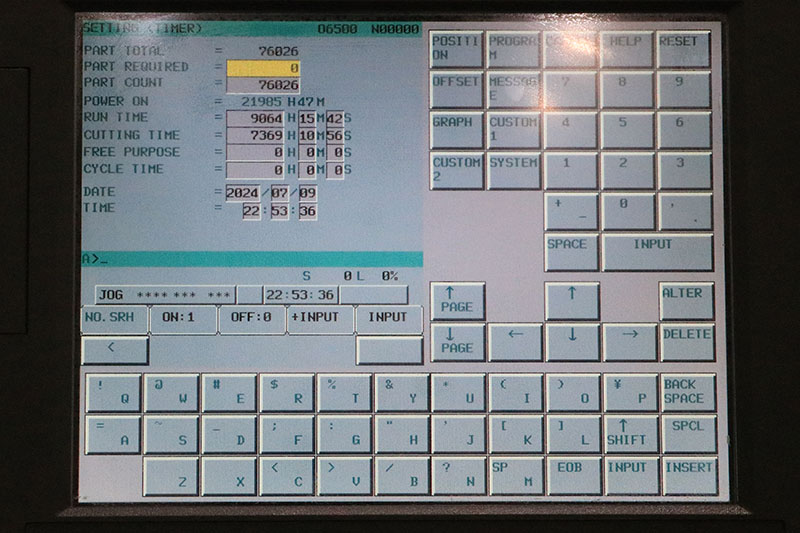

Special Note:

7,369 Cutting Time Hours

9,864 Run Time Hours

21,985 Power On Hours

Swing Over Table .............. 12.6"

Distance Between Centers:...... 20"

Max. Diameter to be Ground .... 12.0"

Max. weight between centers ... 330 lbs.

Grinding Wheel Size:........... 14" x 1.5" x 5

Grinding Wheel Speed:.......... 1,610 RPM

Wheelhead, Total Stroke

(X-axis) ..................... 11.8"

Wheelhead Swivels ............. +/- 30°

Wheelhead Automatic Infeed .... 0.00001" to 0.004"

Minimum Increment ............. 0.00001"

Wheelhead Power rapid Stroke .. 1.5"

Rapid Feedrate ................ 157" IPM

Manual Pulse Generator ........ 0.00001", 0.0001", 0.001"

Grind Feed Overide:............ 0 - 200%

Max. Table Travel ............. 34"

Swivel Angle .................. 0 - 5°

Power Table Traverse Speed .... 0 to 394" IPM

Manual Pulse Generator ........ 0.00001", 0.0001", 0.001"

Sparkout, Plunge Grind ........ 0 to 10 Seconds

Sparkout, Traverse Grind ...... 0 to 10 Cycles of Table

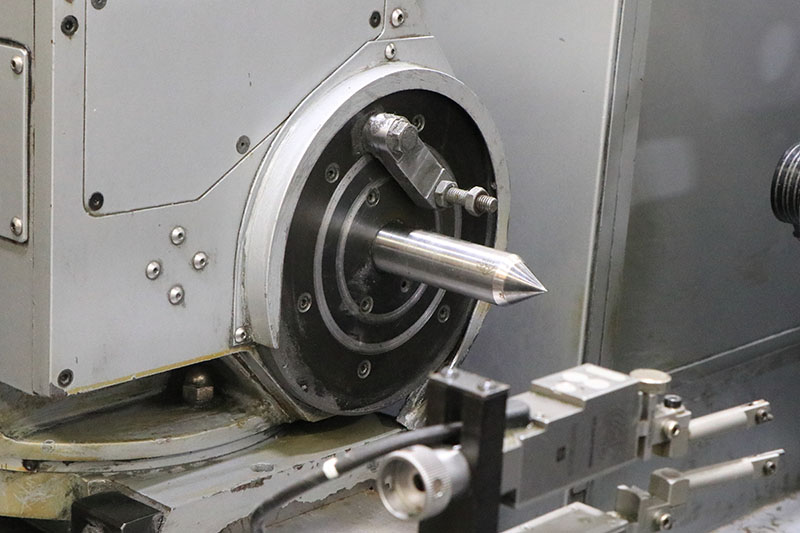

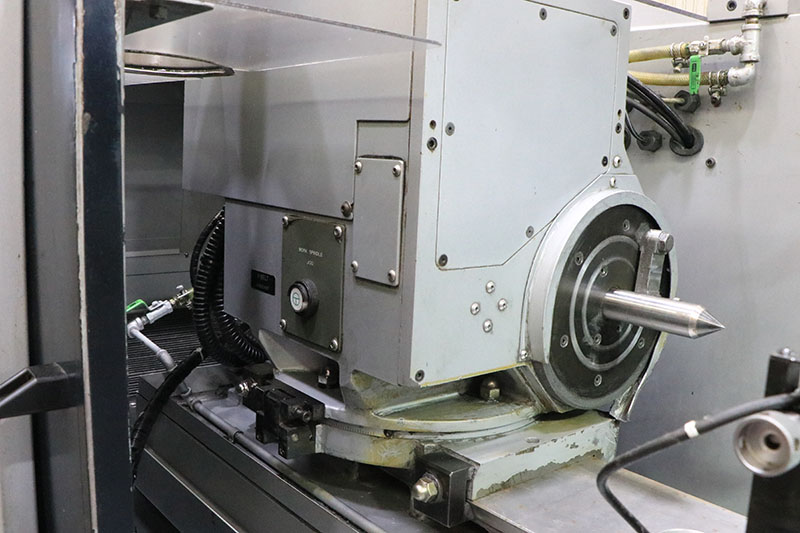

Work Head Center Taper ........ MT #4

Work Head Swivel Angle ........ +30°/- 90°

Work Head Spindle Bore ........ 0.7"

Work Head Spindle Speed ….... 10 - 500 RPM

Tailstock Taper ............... MT #4

Tailstock Spindle Stroke ...... 1"

Grinding Wheel Spindle Motor .. 7.5 HP

Wheelhead Feed Motor .......... 1.6 HP AC Servo

Table Feed Motor .............. 1.6 HP AC Servo

Work Head Spindle Motor ....... 2.4 HP AC Servo

Machine Weight:................ 10,500 lbs.

Approx. Dims. of Machine .... 134" x 92"D x 77"H

Machine Features:

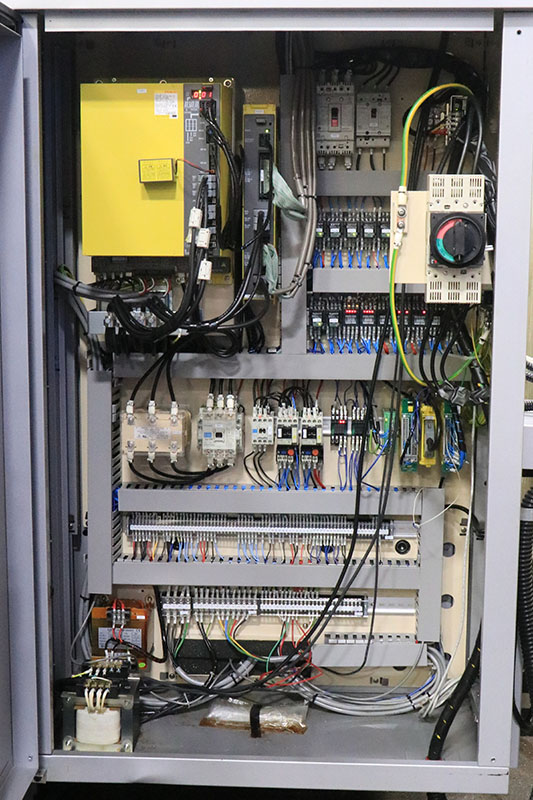

Fanuc Oi-TB CNC Control

Two Axis Simultaneous CNC Control

CNC Programming, for Contouring, Multiple Diameters,

& Dressing

Minimum Programmable Increment 0.00001"

Conversational or G and M Code Programming Std

Quick, Easy Set-up, Designed for Optimum Operator

Convenience

Fanuc Red Cap Servo Motors for the Axis Movements

Low Friction Material is Applied to the Sliding

Surfaces of Slide Table & Wheel head.

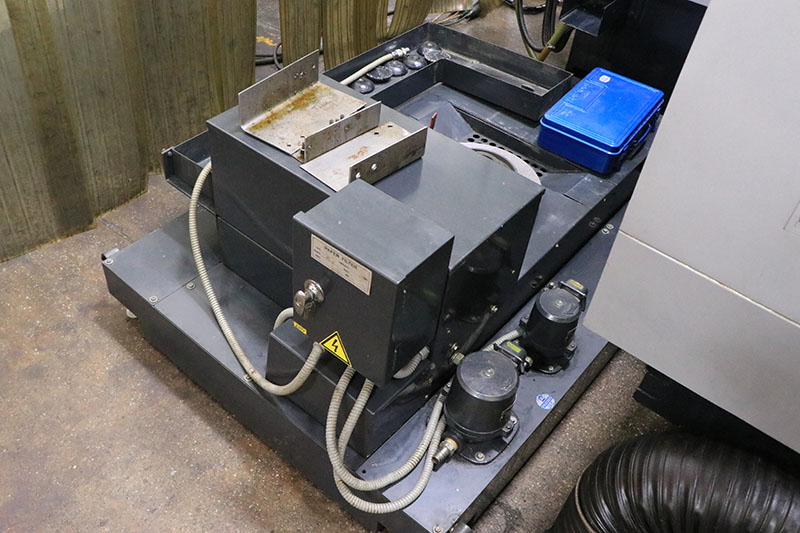

Coolant System

Machine is Wired for 3/60/220 Volts, 20 KVA Service

Equipped with:

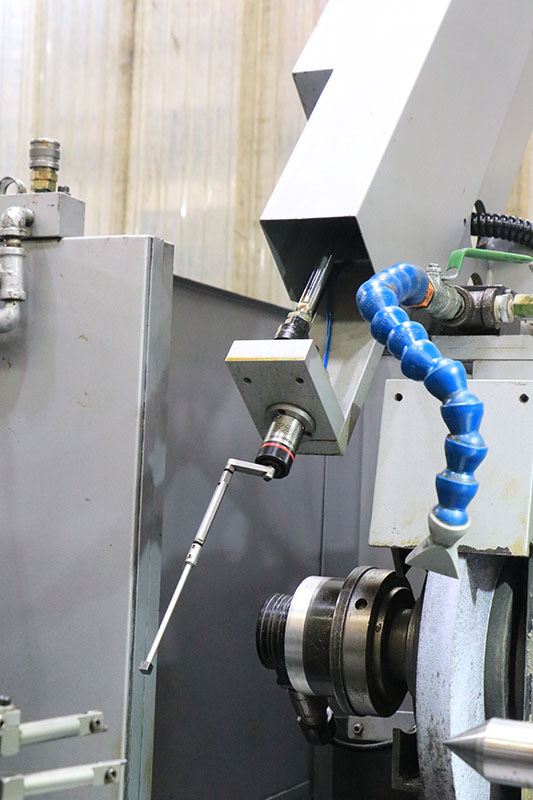

Laeral Locator

Marposs "E-9" In-Process Gauge Amplifier

Marposs "Unimar S" Measuring Gauge Heads

SBS Automatic Wheel Balancing System

Coolant System with Paper Filtration

Dial Indicator for Table Swivel Adjustment

Machine Tool Enclosure

Work Light

Special Note:

Swing Down I.D. Attachment & I.D. Spindle Can

Be Purchased from Okamoto **

** Just Arrived - Low Hours, Beautiful - Original Paint **

** Superior Condition & Appearance **

** Inspect Under Power in Our Harrison, NJ Warehouse **