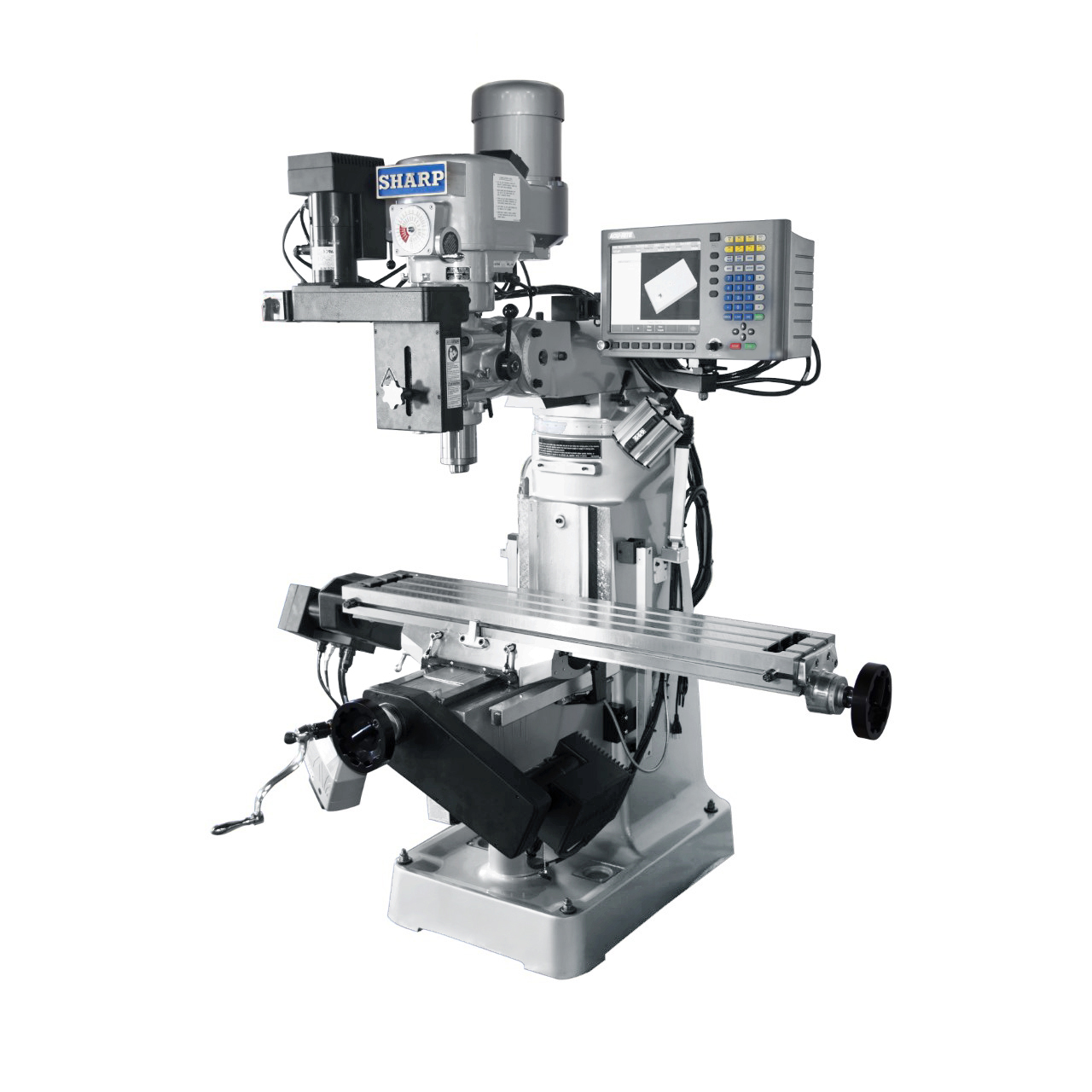

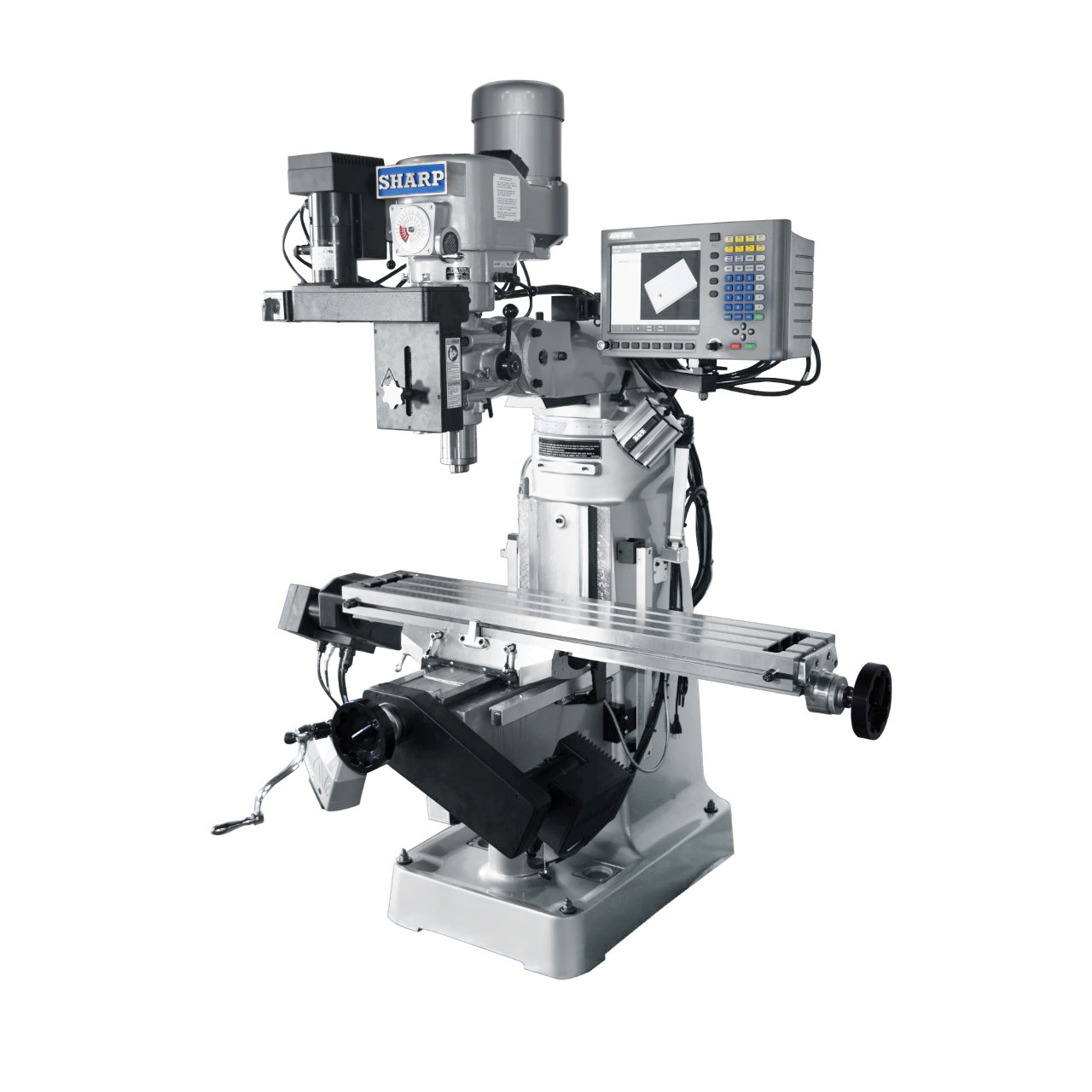

NEW SHARP CNC VERTICAL KNEE MILL

MODEL: TMV/MP-2

SPECIFICATIONS

TABLE:

WORKING SURFACE: ...................... 10"X50"

T-SLOT NUMBER, SIZE: .................. 3, 5/8"

CAPACITY:

TABLE TRAVEL: ......................... 15.5" X 28"

RAM TRAVEL: ........................... 18.5"

QUILL TRAVEL (Z-AXIS): ................ 5"

KNEE TRAVEL: .......................... 15.3"

SPINDLE TO COLUMN (MIN-MAX): .......... 9.8" - 28.3"

SPINDLE TO NOSE TABLE: ................ 1.6 - 16.9"

SPINDLE:

MOTOR: ................................ 3 HP

WIREIG VOLTAGE: ....................... 220/440V, 3 PHASE, 60HZ

TAPER: ................................ R-8

SPPED (VARI-SPEED): ................... 60-4,500 RPM

QUILL FEED (IPR): ..................... 0.0015", 0.003", 0.006"

HEAD TILT; LEFT TO RIGHT: ............. 90°

HEAD TILT UP-AND-DOWN: ................ 45°

DIMENSIONS AND WEIGHTS:

FLOOR AREA: ........................... 70" X 75" X 88"

NET WEIGHT: ........................... 3700 LBS.

TOTAL POWER CONSUMPTION:

220V: ................................. 3KVA/15 AMPS

440V: ................................. 3KVA/7.5 AMPS

STANDARD ACCESSORIES:

MANUAL DRAW BAR

HARDENED AND GROUND BOXWAYS

FRONT AND REAR WAY COVERS

AUTOMATIC LUBE SYSTEM

TOOL KIT INCLUDES: MACHINE MANUAL, HALF NUT WRENCH, WRENCH 17M, 19M,

SET OF 6 ALLEN WRENCHES, PHILLIP SCREW DRIVER, FLAT HEAD SCREW DRIVER,

OIL CAN, GREASE GUN, REAR WAY COVER BRACKET, PIN FOR INDICATOR,

CAN OF PAINT

FEATURES:

VERTICAL KNEE MILL WITH MILLPWR-G2 3 AXES (TABLE,SADDLE AND QUILL) CNC SYSTEM BY ACU-RITE

DIGITAL SERVO DRIVE SYSTEMS FOR X, Y, AND Z AXES TRAVEL

ABLE TO PERFORM 3-D CONTOUR WORK

PRECISION-GROUND BALL SCREWS WITH PRELOADED BALL NUT ASSEMBLIES

3-AXIS (TABLE, SADDLE, QUILL) DIGITAL READOUT SYSTEM

AUTOMATIC LUBRICATION SYSTEM

SAFETY HAND WHEELS

MACHINE CONSTRUCTION FEATURES SAME AS SHARP MODELS LMV, LMV-50

MILLPWR-G2 CNC SYSTEM FEATURES:

HARDWARE

12.1" FLAT-PANEL HIGH RESOLUTION DISPLAY WITH 3 D GRAPHICS, COLOR KEYPAD SIMPLIFIED NAVIGATION THAT ELIMINATES MULTIPLE MENU SCREENS RS-232 PORT, USB (2), ETHERNET 1.4 GHZ PROCESSOR, 2.5 GB FLASH INTERNAL STORAGE PROGRAMMABLE SPEED (WITH OPTIONAL DVS HEAD) SOFTWARE USER FRIENDLY CONVERSATIONAL PROGRAMMING FORMAT.

NO PRIOR PROGRAMMING EXPERIENCE IS NECESSARY.

STANDARDIZED MENUS MAKE IT EASY TO PROGRAM COMMON FEATURES

LIKE LINES, ARCS, POCKETS, BOLT HOLE PATTERNS, ISLANDS,

SPIRALS AND ELLIPSES. TO ADD A FEATURE TO THE PROGRAM, SIMPLY PRESS A FUNCTION KEY AND THEN FOLLOW THE PROMPTS.

PERFORM COMPLEX CALCULATIONS TO SOLVE GEOMETRY AND TRIGONOMETRY PROBLEMS.

EDIT INDIVIDUAL STEPS OR MERGE WHOLE OR PARTIAL PROGRAMS ALREADY CREATED BY USING FUNCTIONS SUCH AS:

MIRROR/REPEAT/ROTATE, EXPLODE, REVERSE STEP, REVERSE PATH, CHANGE STEPS, DELETE STEPS, COPY/MOVE STEPS.

IMPORT GEOMETRY DIRECTLY FROM A CAD FILE USING THE MILLPWR’S DXF FILE INPUT-FOR FASTER PROGRAMMING AND FEWER ERRORS.

PREVIEW EACH STEP WITH IMMEDIATE-PART- VIEW GRAPHICS – THE CONSOLE AUTOMATICALLY SHOWS A GRAPHIC REPRESENTATION OF EACH STEP ONCE IT IS CREATED IN A PROGRAM.

PROGRAM TO MILL AT OR TO A SPECIFIED DEPTH AUTOMATICALLY.

ABLE TO IMPORT AND RUN G-CODE FILES FROM CAD/CAM PROGRAMS TO

MACHINE FULL 3-D CONTOURED PARTS.

AUTOMATICALLY CONTROL SPINDLE’S SPEED AND/OR DIRECTION OF THE MACHINE (MACHINE HAS TO BE EQUIPPED WITH THE DVS HEAD-AN OPTIONAL ITEM, PLUS THE PROGRAMMABLE SPEED OPTION).