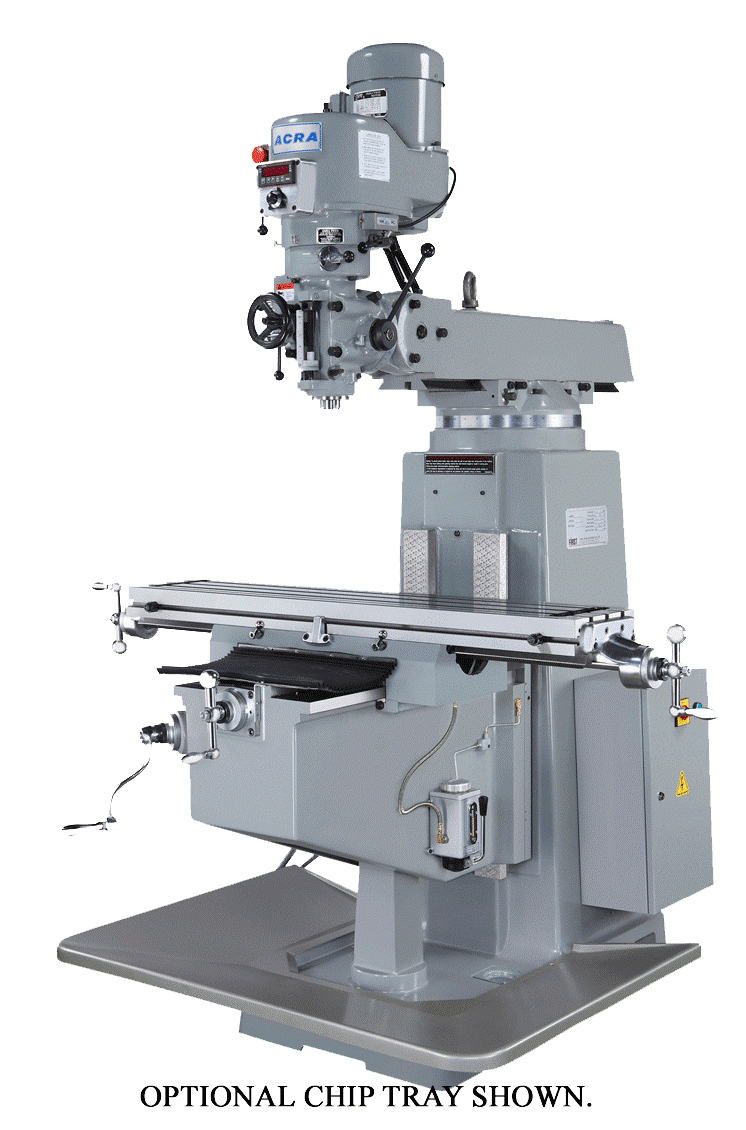

NEW SHARP LMV-49K-DVS PACKAGE VERTICAL MILL

WITH

- 3-AXIS DIGITAL READOUT (quill, saddle, table)

- DIGITAL VARIABLE HEAD (DVS)

- TABLE POWER FEED

TABLE

Working surface 9” x 49"

T-slot number, size 3, 5/8"

CAPACITY

Table travel (X,Y,Z) 36.6" x 12" x 5"

Ram travel 12"

Knee travel 16"

Spindle to column (min-max) 6 3/4" - 18-1/2"

Spindle to nose table 2 1/8” - 18"

SPINDLE

Motor 3 HP

Spindle Nose Taper R-8

Digital Variable Speed 60 ~ 4,500 RPM

Quill feed (IPR) 0.0015”, 0.003”, 0.006"

Head swivel 360º

Head tilt; right-to-left (each way) 45º

Head tilt up-and-down (each way) 45º

DIMENSIONS AND WEIGHT

Floor area (w x d x h) 52" x 55" x 82.7"

Net weight 2280 Lbs.

STANDARD ACCESSORIES:

DVS Head

Hard-chromed ways

Precision Ground and Flaked Table

Unique Double Nut Backlash System

Double Fan Cooling System

Cutler Hammer On/Off Switch

One-shot lube system

Front and rear rubber way covers

Tool kit

OPTIONAL ACCESSORIES:

440 V Transformer - 3HP

Auto Lube Pump w/ 2 adjustments

6" Kurt Vise with Swivel Base D688

Righ Angle Milling Attachment with Arbor

Drill Chuck & Drill Arbor

Coolant system with chip pan

Maxi Torque Rite Power Draw Bar

Riser block (4”, 7”)

R-8 Collet Set of 11 (1/8"-3/4" by 1/16")

Clamping Kit

Halogen work light

Spare Kit

Features, Function, & Benefits:

ISO 9002 Certified:

Quality Up To World Industry Standards.

Meehanite Casting:

Highest Grade Of Casting Possible.

A Pair Of Precision ABEC-7 Angular Contact Bearings To Support Spindle. The Quill Is Ground And Chromed To Fit The Housing:

This Insures A Spindle Run out Of .0004” T.I.R.

Motor Shaft And Varidrive Pulleys Are Dynamically Balanced, Then Chromed For A Flawless Fit, Ground Ribs On Inside Diameter:

For Smooth Speed Changes.

Motor Shaft Has An Oil Channel In The Center That Is Fed By A Grease Fitting On The Lower End:

To Keep Vari-Drive Pulley Moving Smoothly On The Shaft.

This LMV-49DVS Mill Uses A Roller Bearing For The Lower Support Of The Shaft

It Ensures Proper Loading, Support And Alignment It Also Prevents The Shaft From Being Distorted By The Tension Of The Belt:

For Quiet, Accurate Operation At Any Speed For Years And Years.

One Shot Lubrication System:

For Lubrication Of Ways And Lead Screws. (X,Y And Z-Axis)

Hand Scraped Saddle And Knee:

For Better Oil Retention. It Avoids Having Chips And Dirt Embed In The Knee And Damage The Sliding Surface.

Oil Groove Are Milled:

For Maximum Lubrication On All Wear Areas.

Table And Saddle Backlash Is Controlled By Double Nut Design:

Keeps Lead Screw In Contact With Bronze Nuts An All Times To Keep Backlash At .0008” Within 20”.

Table And Saddle Are Mounted With Thrust Bearings That Are Pre Loaded:

Eliminating Endplay For Precisely Controlled Lateral Movement.

Patient Knuckle Design Uses 6 Bolt 3 Per Side, Securing Them From The Outside:

This Method Locks The Head Securely Resulting In Better Accuracy And Performance.