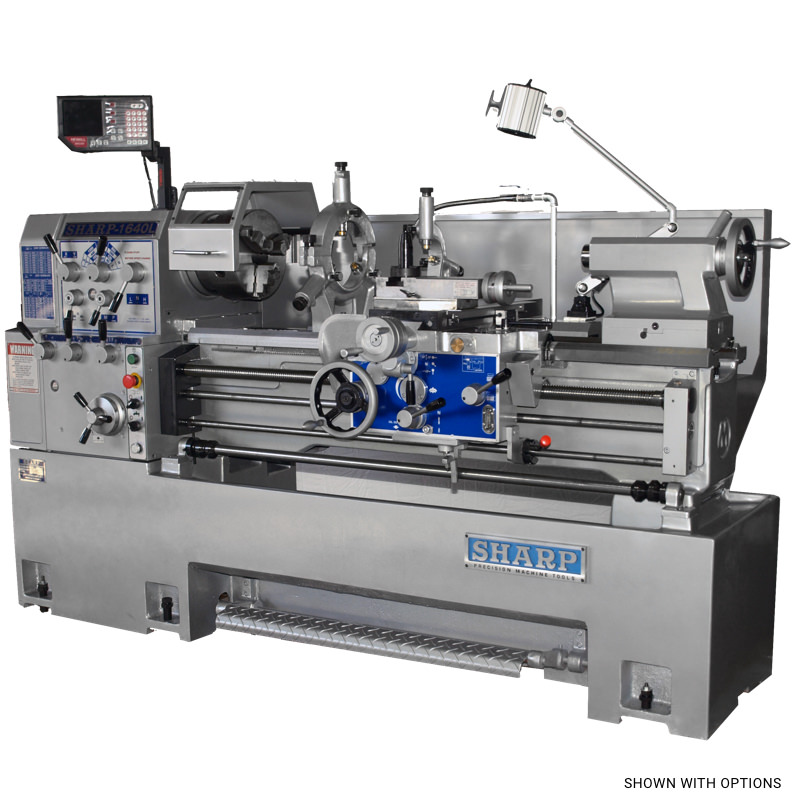

NEW Sharp 1660L Precision Lathe

STANDARD EQUIPMENT:

Bison 3-jaw 10” Chuck

Face Plate (16”)

Steady Rest w/bronze tip (1/2” to 6”)

Coolant System

Full Length Splash Guard

American Tool Post

6” Diameter Back Plate

Threading Dial

Center Sleeve (MT #5 x 3)

Dead Centers (MT #4x1 and MT # 5 x1)

Follow Rest (0.59” – 2.76”)

Halogen Work Light

Longitudinal carriage stops

User can choose either 220V or 440 V application. 575 V needs an optional transformer

Tail Stock & Tool Kit includes:

Machine Manual, Half Nut Wrench, Wrench 17m, 19m, Set of 6 Allen wrenches, Phillip Screw Driver, Flat Head Screw Driver, Oil can, Grease Gun, Rear Way Cover Bracket, Pin for Indicator, Can of Paint

FEATURES:

D1-8 Cam-lock, 3-1/16” Hole

Direct Selection For Inch/Metric Threads

One Piece Cast Meehanite Bed

7-1/2 Hp Spindle Motor

12-Speed Gear Head (40-2,000 Rpm)

Geared Head Model Wired 220V or 440V. Please specify.

SPECIFICATIONS:

Capacity

Swing Over Bed: 16”

Swing Over Cross Slide: 8-3/4”

Travel of cross slide: 9-1/2”

Swing Over Gap: 24.38”

Width Of Bed: 11.75”

Width of Gap: 9.75”

Center height form top of compound: 1.9”

Distance Between Centers: 60”

Headstock

Spindle Nose Type: D1-8 cam-lock

Spindle Bore: 3 1/16”

Spindle Speeds: High 235-2,000 RPM / Low 20-170

Taper of Spindle Bore: MT#6

Taper of Center: MT#4

Threads and Feeds

Longitudinal Feeds – in/rev (18) 0.002 - 0.032”

Cross Feeds – in / rev 0.0001 –0.0094”

Inch Threads (40): 4-56 tpi

Metric and Module Threads: 0.5-7mm

D.P. Threads (36): 4-56 mm

Lead-screw Pitch, Diameter: 4 tpi, 1-3/8”

Carriage

Cross Slide Width 8.7”

Compound Rest Travel: 4.9”

Compound Width: 4.5”

Bed

Bed Length: 77”

Bed Width: 11-3/4”

Tailstock

Quill Travel (graduated): 5”

Quill Diameter: 2-1/4”

Quill Taper: MT#4

General

Spindle Motor: 7-1/2 hp

Net Weight (approx.): 4,100 LBS

Standard Color: Gray

Specifications may be changed or improved without notice.

Electrical:

Voltage: **230/460V

Phase: Single or 3 phase

Total Power Consumptions

230V: 8KVA/25 amps

460V: 8KVA/12.5 amps

Options: (call for pricing)

4 - Jaw 12” Chuck (QU)

3 - Jaw Chuck 10” (Bison)

3 - Jaw Chuck 12” (Bison)

4 - Jaw Chuck 12” (Bison)

Micrometer Carriage Stop

4-Way Toolpost for 16” Swing Lathe

Taper Attachment (factory installed)

Roller Jaws for Steady Rest

(Extra) Steady Rest 16” for Lathes (1/2 – 6” Capacity)

Steady Rest for 16” Lathes (4 – 9” Capacity

Drill & Arbor (JACOBS)

Quick Change Tool (7 pcs) Holder Set (Aloris)

Live Center – MT#4

5C Collet Set (1/8” to 1-1/16” by 1/16”) 16 pcs.

5C Collet Closer for 16 / 18” Lathe (Atlas)

575 V/440V/380V transformer, please select

10 HP motor in lieu of 7.5 HP ( factory order)

DIGITAL READ OUT SYSTEMS:

Fagor 20i D.R.O.

Fagor 40i D.R.O

Acu-Rite 203 S D.R.O

Newall DP700 D.R.O.

Newall NMS D.R.O.

Chuck Guard( factory order only)

Movable horizontal chuck guard ( factory order)

Tool guard ( factory order only)

Lead screw guard ( factory order only)

Guard behind spindle( factory order only)

UL(to meet state of California) /CSA switch board/UL motor/CSA Pump in lieu of regular version (factory order only)

UL/CSA-16 ( factory order only)

** NOTE: SHARP DOES NOT PROVIDE UL/CSA STICKERS ON THE MACHINES, BUYERS NEED TO CONTRACT A LOCAL AGENCY TO REVIEW THE ISSUES THEN PUT "COMPLIANCE" STICKERS ON THE MACHINES AFTERWARDS.

All heighted items are factory order only and all guards are needed for UL compliance certificate

*** UL compliance certificate issued by CSA Group in Los Angeles with all highlighted parts above $4,700

*** NFPA 79 parts upgrade and self certified by Sharp, $3,500